Material: Corn starch, Plant Fiber, PLA etc Product: Calcium Carbonate Granules, Talcum Granules, Starch Based Granules, Plant Fiber Based Granules Etc (Formula for Free)

1.Machine Investment is relative low;

2.Energy Saving. The machine extrude sheet directly to forming;

3.One machine line produces variety of products by changing molds;

4.One machine line uses several kinds materials to produce products;

5.We provide the production formula of degradable tableware, and the certificated degradation rate reaches 94% within 28 days;

6.The machine line is also able to produce starch-Plant fiber based products;

7.Output capacity is large, one machine line is able to produce more than 100000 standard fast food container a day;

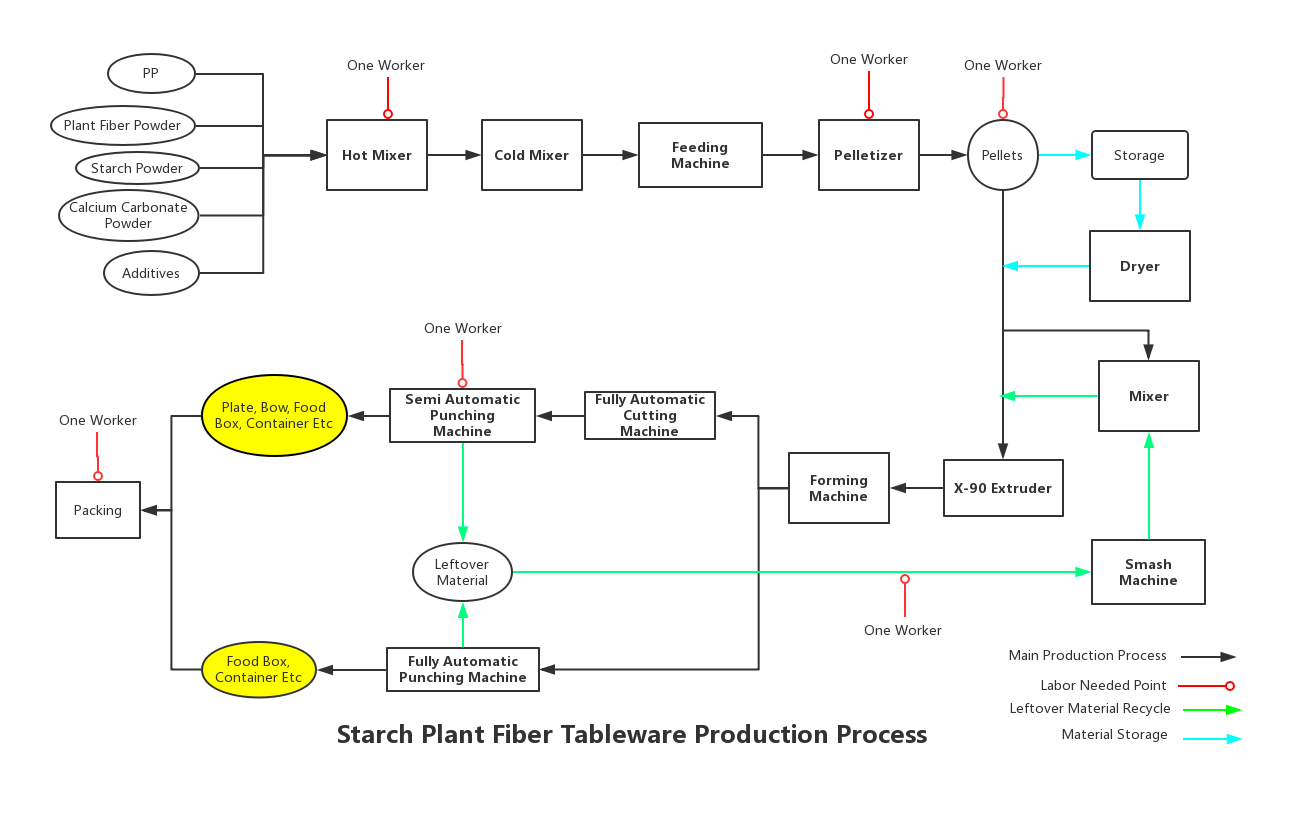

8.Labor saving, the Fully Automatic line only requires one worker for packing during the whole production process;

9.No material wastage, the left-over material can be reused after smashing and remixing.

Hot mix | Cold mix | ||

Total volume(L): | 300 | Total volume(L). | 600 |

Effective volume(L | 225 | Effective volume(L). | 320 |

The amount of feed(Kg) at a time | 150 | The amount of feed(Kg) at a time | 150 |

Mixing time(min). | 10-12 | Cool down time (min). | 8-15 |

Yield(h/kg). | 500 | Spindle speed(r/min). | 80 |

Spindle speed(r/min). | 0~950 | Cooling charge temperature | ∠40 |

How to heat it | Special mechanical oil with a ignition point of more than 320degrees C on the oil heating medium | Cooling price (C) | Constant hot water |

Material temperature (C) | 140 | Cooling price pressure(MPa). | ∠0.1 |

Drain compressed air(MPa). | 0.39-0.49 | Cooling water temperature (°C) | ∠15-20 |

Temperature control | Automatic. | Temperature control | Automatic. |

The way it is discharged | Pneumatic. | The way it is discharged | Pneumatic. |

Motor model | YD250M4V1 | Motor model | YD160-4 |

Motor power | 55KW | Motor power | 11KW |

Motor power | 5t/h | The amount of gas consumed | 0.4 |

Brazilian Customers Come to Visit Machine Show

Brazilian Customers Come to Visit Machine Show

Acceptance inspection--Russian Client

Acceptance inspection--Russian Client

2011 FCE

2011 FCE