Tomato Paste Processing Line

The 20 tons is the end product, that is the tomoto paste end product. (if your fresh tomato is from 4-5brix, that is to say, you will need 120-140tons per day)

● Project Information

1. The 20 tons is the end product, that is the tomoto paste end product.

(if your fresh tomato is from 4-5brix, that is to say, you will need 120-140tons per day)

2. Working hours per day is 16 hours, we would do production 300 days in a year.

3. The best brix of tomato paste product is 28 to 30.

4. Three kinds of products, including 200 kg drum, tin can and pouch (details are as follows)

5. About standby generator set in case of power outage, we can also supply, but the price will be confirmed when you confirm all the final and accurate quotation of whole tomato paste processing line, when you come to China.

● Whole Line Introduction

A. Fresh Fruit(tomato) Washing Unit

A-1 clapboard elevator

Capacity: 6T/h

Heightxwidth: 5500x1000, motor of 2.2KW and adjustable geared motor 20~100RPM, pitch 38.1 anti-corrosion roller chain.

A-2 air-blow washer and sorting machine

Capacity: 6T/h

stainless steel centrifugal pump ; oxygen pump; lifting speed can be adjustable,size of elevator and sorting roller platform is φ51, sorting table with guardrail, platform is made of stainelss steel anti-skidding checkered plates

A-3 clapboard elevator

Capacity: 6T/h

2.2KW and speed reducer 20~100RPM, stainless steel plate, 4500 x 1000mm

B. Pulping Unit

B-1 crusher

Capacity: 6T/h

SUS304, power is about: 18.5KW

B-2 tempoary storage tank

Capacity: 1000L

SUS304, single, installed on the top of the lamp hole mirror, CIP cleaning ball, bottom flange type outlet, with low level, four adjustable legs

B-3 screw pump

Capacity: 6T/h

Manual speed control, outlet pressure 0.6Mpa

B-4 tubular heat exchanger heater

Capacity: 6T/h

Food sanitation, tube heating , with the inlet steam pressure system, automatic control temperature with a outlet thermometer

B-5 double beater

Capacity: 6T/h

SUS304, first mesh 0.8mm , secondary mesh 0.4mm, power 37KW

B-6 buffer storage tank

Capacity: 1000L

single, circular, half open, bottom flange outlet, high and low level, pure water inlet

B-7 screw pump

Capacity: 6T/h

Manual speed control, outlet pressure 0.6Mp

B-8 crusher platform

carbon steel frame, stainless steel checkered plate, size: 5000mm×2500mm, central draining

B-9 pulping operation platform

steel bracket,stainless steel checkered plate, size:3500mm×2500mm, central draining

C. Evaporator and Concentrating Unit

C-1 buffer storage tank

Capacity: 5000L

SUS304, PU insulation, conical head, pull rod valve at bottom discharge , sealed manhole, ladder,high and low level, sampling valve, the top offset vertical mixing, anti-vortex plate, digital thermometer, CIP cleaning ball, adjustable support legs

C-2 centrifugal pump

Capacity: 10T/H

Food grade, mechanical seal, ABB motor, 36M lift

C-3 double-effect forced circulation evaporator

Capacity: 4T/H

SUS304, automatic PLC control, the British Spirax Sarco steam pressure regulating valve system, inlet temperature sensor, pressure sensor, tower water cooling

C-4 batch storage tank

Capacity: 5000L

SUS304, single layer, digital thermometer, sampling valve, sealed manhole, ladder, top offset vertical mixing, high and low liquid level sensor, adjustable legs

C-5 rotor pump

Food grade rubber seal, variable frequency speed regulation

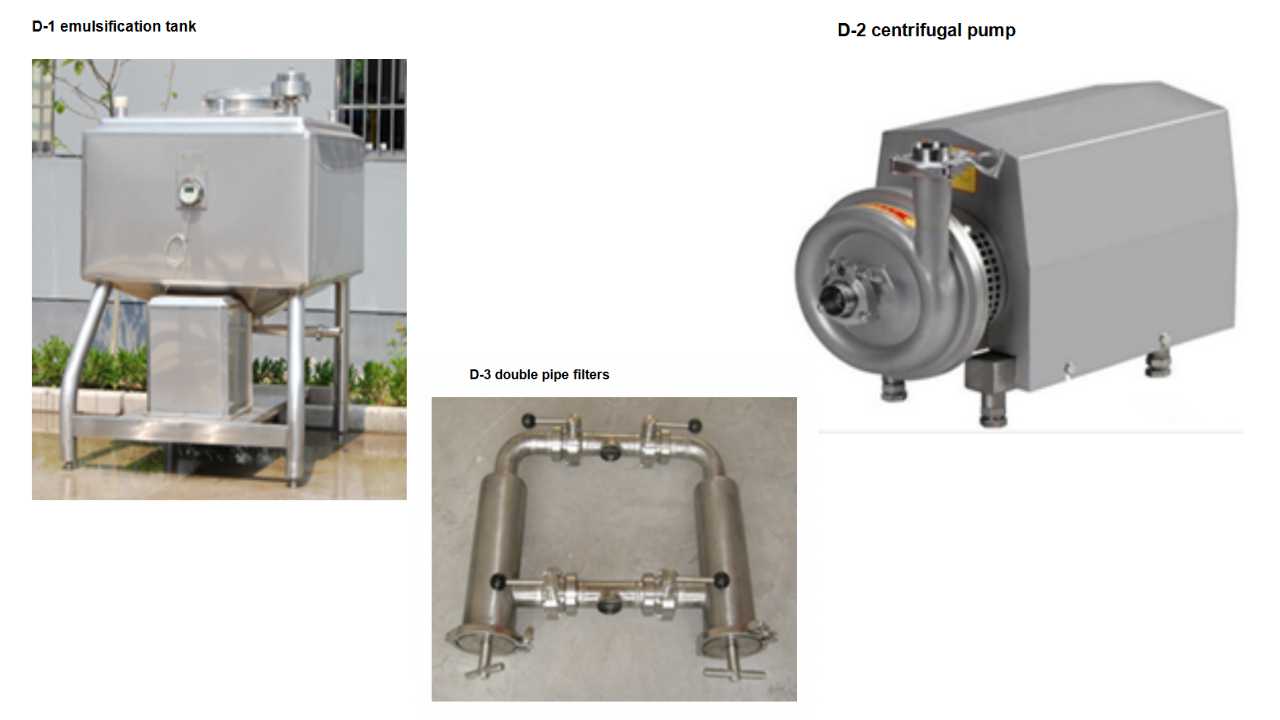

D. Dissolving Unit

D-1 emulsification tank

500L

Material is SUS316, insulation, bottom fast emulsifying head,digital show thermometer, adjustable legs

D-2 centrifugal pump

5T/h

Material is SUS316, pump lift is 36 meters,machinical sealing

D-3 double pipe filters

5T/h

Material is SUS316,duplex pipe,stainless steel filter 100 meshes

D-4 material feeding platform

SUS304,1200x1500x1200mm

E-Blending Unit

E-1 screw pump

Q=1T/H

sanitary grade, outlet pressure≤0.6MPA, movable, with fuction of lifting

E-2 blending tank

1500L

Material is SUS316, insulation, dmiller jacket, central scrapper blender, conical head,sealed manhole,breath vent, sample valve, digital show thermometer, anti vortex plate, adjustable legs

E-3 screw pump

Q=3T/H

Sanitary grade, outlet pressure ≤0.6MPA, frequency converted control

E-4 steam conditioning and temperature control system

south korea brand pressure reducing valve, Germany Burkert steam regulating valve etc.

F sterilizing and filling system

F-1 Tube-in-tube UHT sterilizer

Capacity: 1T/H

SUS304, Tube-in-tube type, automatic PLC control, tower water cooling , the British Spirax Sarco steam pressure regulating valve, sterilization temperature 110 ℃, 60S.

F-2 aseptic large bag filling machine

Q=1T/H

Aseptic large bag filler, 220kg, double heads , automatic control, self-leaning system, with Motor drum rolling conveyor

F-3 drum rolling conveyor

carbon steel support with antirust painting, Galvanized rollarounds, effective width 7500mm, length 10000mm.

F-4 high position storage tank

1000L

Material is SUS316, insulation, central scrapper blender, conical head,sealed manhole,breath vent, sample valve, digital show thermometer, anti vortex plate, adjustable legs

F-5 high level platform

SUS304,3000x3000x2000mm

F-6 filling sections

♢ standing pouch filler

speed:4000-5000p/h; capacity: 100-200g; motor power:1.5KW; pressure:0.5MPA

♢ tin can filling machine

4000pcs/h

Including washing tin can, filiing, capping, conveyor. Tin can:250ml

♢ can unloading machine

4000can/h, full-auto touch screen control, include can inputting conveying chain, carbon steel; can unloading main system, carbon steel frame, main board stainless steel; operation frame, carbon steel.

♢ empty can conveyor

4000 cans/h,lengh:5m

♢ empty can washer

4000 cans/h, hank dragon type, sus304 material, include stainless steel water spraying tank, water spraying pipe, water outlet, support

♢ full can conveyor

4000 cans/h, length 60m, the actual length will be caccording to the final drawing

♢ spraying&sterilization cooling tunnel

main material SUS304, plate type heat exchanger, circulation centrifugal pump, plastic conveying mesh belt, 4000C/H, cooling time 20min, outlet temperature around 40℃.

♢ blow dryer

SUS304, 4000pcs/h

♢ automatic labelling mahcine

4000C/H

♢ printer

♢ platform: SUS304, dimension: 2000x500x1200mm

♢ conveyor and lubricating system

with lubrication liquid barrel, with measuring pump

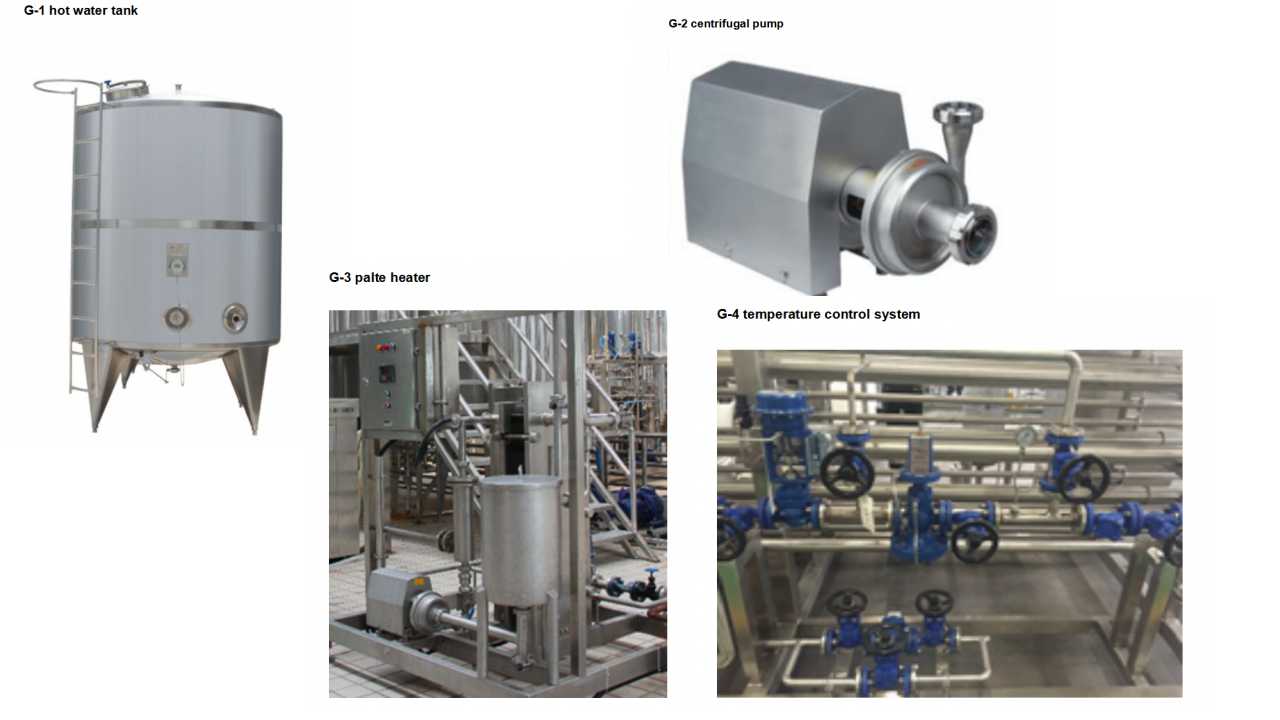

G. Hot Water Unit

G-1 hot water tank

SUS304, 60mm PU heat preservation, top and bottom 15° conical head, airtight manhole, respiration valve, the digital display thermometer, overflow tube, anti-vortex plate, pure water inlet, hot water reflux nozzel, glass tube indicator, ball float type sensor of high,middle, low level, bottom discharge valve with pull rod, adjustable legs, ladder

G-2 centrifugal pump

Q=5T/h

SUS304, lift 24 meters, mechanical seal

G-3 palte heater

Q=5T/h

SUS304, steam heating directly, plate Proof Pressure 8kg,60-95℃

G-4 temperature control system

UK Spirax sarco reducing valve, trap system, Chinese famous brand stop valve, steam instrument.

H. CIP system

H-1 semi automatic single circuit CIP

2T×3

SUS304 outer cladding, inner shell SUS316, 3000L acid and alkali tank, 3000L hot water tank, coil tube heating inside the tank, automatic temperature control, single circuit, United States of America concentrated acid and alkali adding system, with two 200L concentrated acid and alkali tank, 2pieces of centrifugal pump (20T/h, head of 24m)

H-2 CIP return pump

20T/H

food grade, self-sucking, mechanical seal

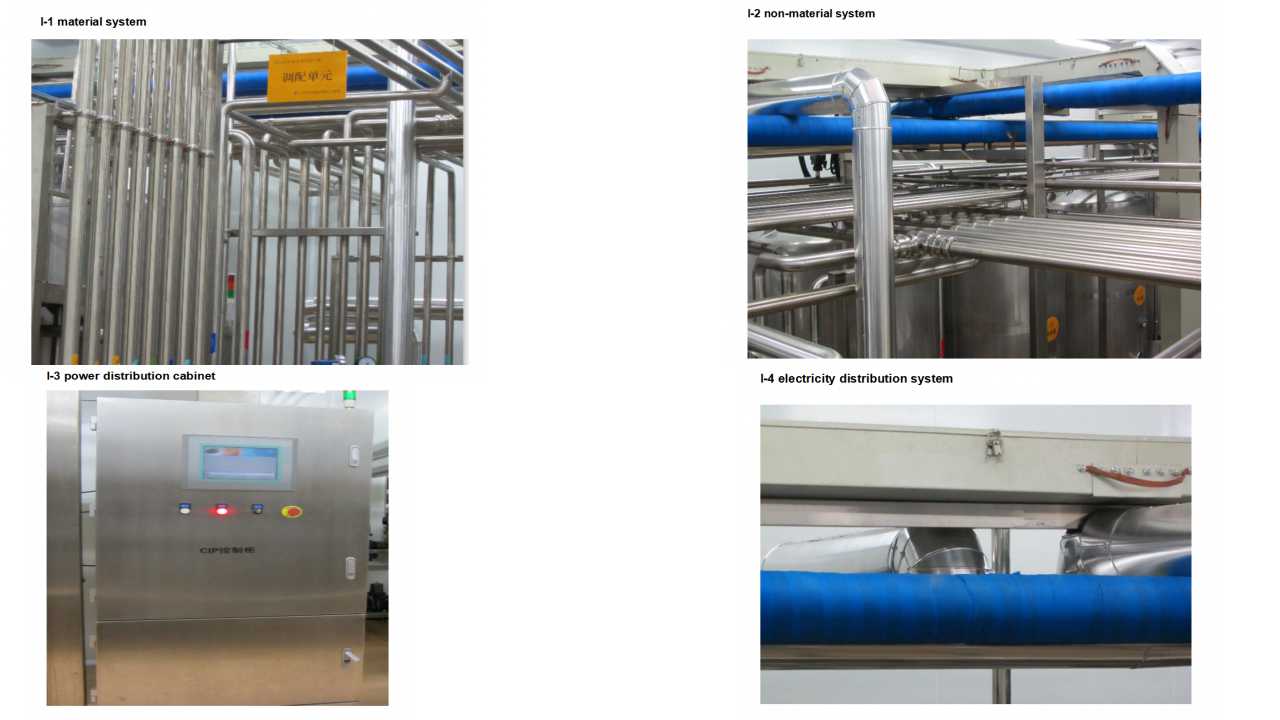

I. Engineering Installation and Others

(in our own factory,ready for shipping)

I-1 material system

national standard

The main workshop offer by our equipment process piping, valves and instrumentation, SMS standard, including the internal installation of CIP system.

I-2 non-material system

National standard

workshop is offer by our equipment of water, water, compressed air, piping and valves, including insulation.

I-3 power distribution cabinet

National standard

Main workshop is offered by our equipment, power distribution cabinet and control cabinet in spot(stainless steel), containing CIP electrical cabinet system.

I-4 electricity distribution system

National standard

Cable bridge of the cable in the main workshop , and the control system, the main cabinet centralized control, control cabinet controlled in spot , obligate the power distribution cabinet.

Brazilian Customers Come to Visit Machine Show

Brazilian Customers Come to Visit Machine Show

Acceptance inspection--Russian Client

Acceptance inspection--Russian Client

2011 FCE

2011 FCE