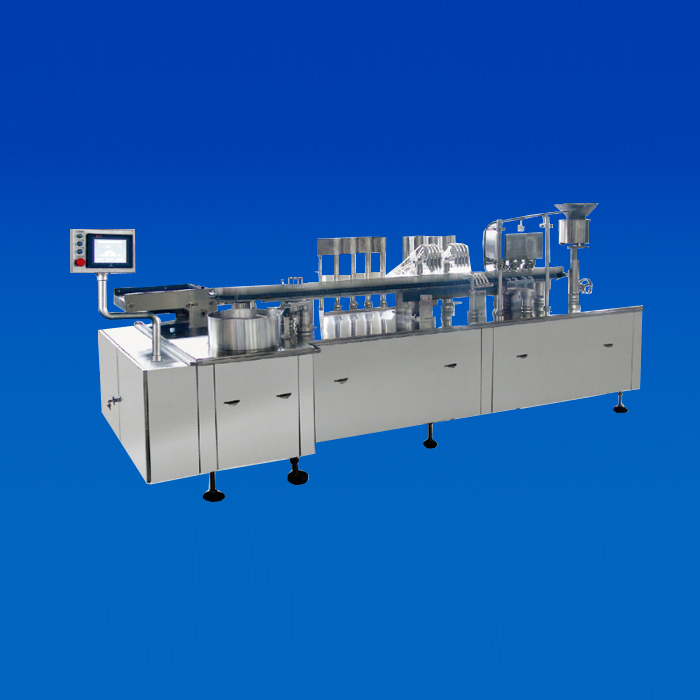

(KG-4) Cartridge Filling-Capping-Stoppering Machine

This production line is developed by our technical personnel based on the former model with imported advanced technology and material

● Photos of Glass Cartridges

(1) Introduction

This production line is developed by our technical personnel based on the former model with imported advanced technology and material; meet domestic packaging materials, well-designed, its performance is macaronis, machine equipment reasonable, mechanism is simple, run stable, easy to operation, easy to clean, choose the best package for one of the project. Meet with China's GMP authentication, to foreign CE authentication target.

The production orders of cartridges are different in nature: the whole filling section - automatic sealing section, separated by a transparent material, to prevent movement of contamination with each other. Slender glass bottles, small port diameter of bottles. So our company is designed using high-precision positioning, to achieve steady state operation.

Detailed works are described below:

● The tunnel sterilizing oven to dry the cartridges through the comb into the bottle filling machine conveyor belt into the big dial, and then run the machine the gap-type transport system, so that the cartridges into the bottle hanging fixtures, each action into four bottle, to order into a different station.

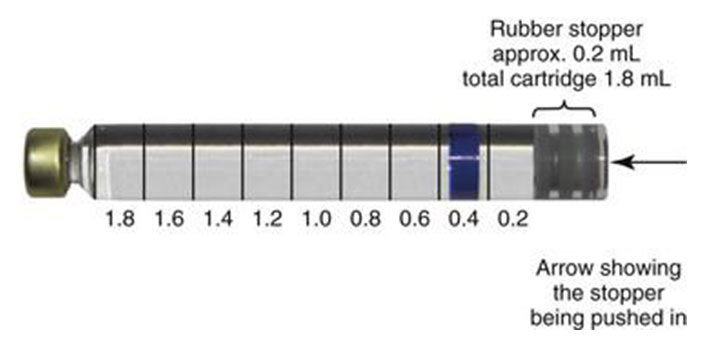

● The bottom of the stopper station

Rubber plug from the hopper through the speed shock vibration, automatic management plug in the same direction into four tracks, feed orbit display with automatic detection of missing plug, no plug transmission signal automatic shutdown, automatic replenishment can be automatically resumed production. Automatic put plug one by one by a robot crawling. Function simultaneously capture four full time, on the plug from the tube station to stopper up the bottom insert, insertion depth 3mm (the plug from the nozzle to the end), insert the body in place to ensure accurate stopper, stopper body movements with precision into the automatic cam control. Bottle with a rubber stopper until the card is running in place, the incumbent test set control, such as the stopper is not position is automatically removed.

● Measure filling station

After stopper the bottom of the cartridges, into the filling station, measure filling system separate pre-filling and not filling. Pre-filling, not filling controlled by the high-precision no-valve metering rotary ceramic / stainless steel pump, and its installed capacity from the servo motor can be used to set the control microcomputer separate fine adjustment. Mechanical filling pump rotated 180 degrees, rotate the cylinder by a high-sensitivity electromagnetic valve control, mechanical cam control pumps up and down stroke, the pump connected to the main driver for mobile devices drive mechanism, the filling needle travel by the cam control.

● No- filling station pumping system

The system is suitable for all kinds of pipe sizes. Pumping system by the suction needle, Ventura vacuum generators draw valve of stainless steel tanks after the liquid composition.

● Capping sealing station

The cartridges filled into the aluminum cover, capping station. This station consists of the hanging body, aluminum cover feeder and cover agencies. Aluminum cover single track feed, lack of cover detection sensor is installed on the feed track, lack cap automatic stop, have cap resume production.

Drug pipe use head put the control aluminum cap from the rail, sealing cap from the paw, move up and down by mechanical cam to complete.

● Remove problematic drug pipe station;

● Drug pipe installs plate sterilization;

The whole process entirely controls by computer PLC, detection and control equipment for all functions.

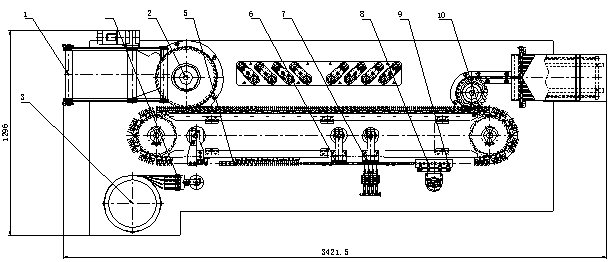

(2) Function Description

1. Automatic inlet bottle belt 2.Inlet bottle dial 3 the plug oscillator

4. Up bottom cap institutions 5. Press stopper test 6.Once filling

7. Secondary filling 8. Capping 9. Capping test 10. Outlet bottle dial

Each part working principle as follows:

● Automatic inlet bottle belt is sterilization drying cartridge enter into the bottle filling machine through the network with a motor drive; put the bottle into the bottle track wheel.

● Inlet bottle dial is inlet bottle network with the bottle into the bottle dial to dial into the folder.

● Up internal oscillator is automatically straightened out the stopper plug into the plug body on the end of the track.

● The body of up bottom plug mainly through the mechanical hand drive, when the stopper is pushed onto the robot turn blocks, robot stopper can be rotated 90 degrees, and sent to tamponade in place, tamponade bit of pressure tamponade cam stopper into the bottle.

● The press stopper test is mainly used to detect the level of tamponade and the presence of bit pressure on the stopper, the level of failure or pressure on the stopper of the bottle did not, will automatically be removed.

● Measure filling separates pre-filling and no-filling. Pre-filling and no-filling controlled by high-precision ceramic rotary pump no-valves and servo motor, its filling volume can be adjusted from the touch screen, the first filling of 80%, the second filling is 20% through pumping fluid system overflow bottle by pumping excess liquid and then pump out, so the exact amount of filling to set, and no bubble bottle after capping.

● When the bottle into the filling time with a photoelectric sensor, the operation of the filling state of the bottles tested, to reach a bottle filling, no bottle no filling bottles and less functional, bottle filling and capping when the optical tracking and detection sensors for bottles, small bottles and if the card will automatically alarm and covered parking.

● Capping adopt four-blade roller capping, rolling the cover to ensure a good seal.

● Capping detection is mainly used to detect capping quality is good or bad, the bottles is not good for capping will be automatically removed.

● Outlet bottle dial is filled by a special agency to cover the bottle rolling it out on the clip from the bottle.

(3) Features

● The servo motor has high precision control, running speed, filling error small.

● Ceramic / stainless steel pump filling sealed good, does not drip, easy to disassemble, easy to clean.

● Under the rubber plug mobile robot 90 degrees accurately and effectively, belt suspended solid and reliable way to transport bottles, filling position accurate.

● Touch screen, PLC control the whole operation, and has a joint protection, safe, reliable, high degree of automation.

● Has CE certificate, standard electrical installation, with the use of operational safety.

● Two time filling and pumping function to eliminate liquid foam.

● Side of the feed roll cover edges smooth, tight seal.

● Equip with plexi glass protection framework.

● The machine designed according to GMP requirements

(4)Technical Parameters

● Suitable bottle size: 2ml cartridges

● Power supply:220V, 60Hz, single phase

● Power: 4.4KW

● Equipped with vacuum pressure:0.25MPa

● Usage: 14m3/h

● Error loading capacity: ≤ ± 1%

● Auto capping ratio≥99%

● Capping pass rate: ≥ 99.7%

● Filling form: 8 head rotating stainless steel pump filling

● Capping form: 4 head capping seal

● Maximum production capacity:80 cartridges/min

● Dimensions (L × W × H): 3430×1320×1700mm

ketchup production line

ketchup production line

Acceptance inspection--Russian Client

Acceptance inspection--Russian Client

2011 FCE

2011 FCE