This machine adopts the PLC, frequency invertor with famous brand, with photoelectricity monitoring, automatic no-feeding stop, high assembling speed, low noise, good stability.

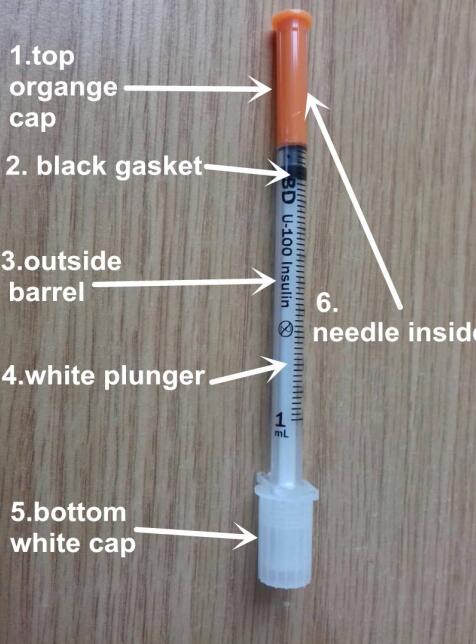

The machine is used for assembling the follow parts:

1. the whole part: which is including top orange cap, outside barrel and needle;

(which is already assembled by KF-1 Insulin Syringe Needle Assembly Machine).

2. plunger

3. gasket

4. bottom white cap

l Product of Samples

The machine is used for assembling the follow parts:

1. the whole part: which is including top orange cap, outside barrel and needle;

(which is already assembled by KF-1 Insulin Syringe Needle Assembly Machine).

2. plunger

3. gasket

4. bottom white cap

(all the above parts to assemble for the final product)

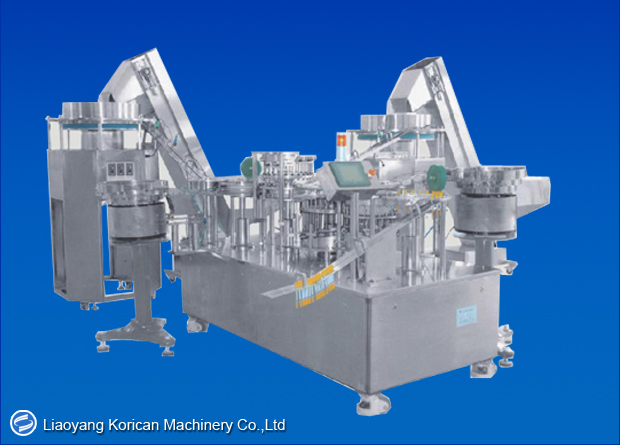

l Machine Features

This machine adopts the PLC, frequency invertor with famous brand,

with photoelectricity monitoring, automatic no-feeding stop,

high assembling speed, low noise, good stability.

Machine structure

Assembly Machine is equipped with vibrating feeder, centrifugal hopper

and automatic raw materials lifting machine.

This machine is with one conveyor to connect with KF-1 Insulin Syringe

Needle Assembly Machine.

Technical Parameters

1. | power supply | 380V,50hz, 3 phases or 220V, 50hz, 1 phase (according to the customer’s need) |

2. | machine speed | 160-180 pcs per minute |

3. | machine packing crate dimension | main motor : 2050x1050x1700 mm;

automatic raw materials lifting machine: 2400x1400x1300 mm;

centrifugal hopper : 1830x920x1720mm |

4. | weight | about 2000kg |

ketchup production line

ketchup production line

Acceptance inspection--Russian Client

Acceptance inspection--Russian Client

2011 FCE

2011 FCE