Non-PVC Soft Bag Forming, Filling and Sealing Machine

Temperature error can be controlled within ± 0.5 ℃,Precise temperature control device can be used to ensure that all qualified membrane。

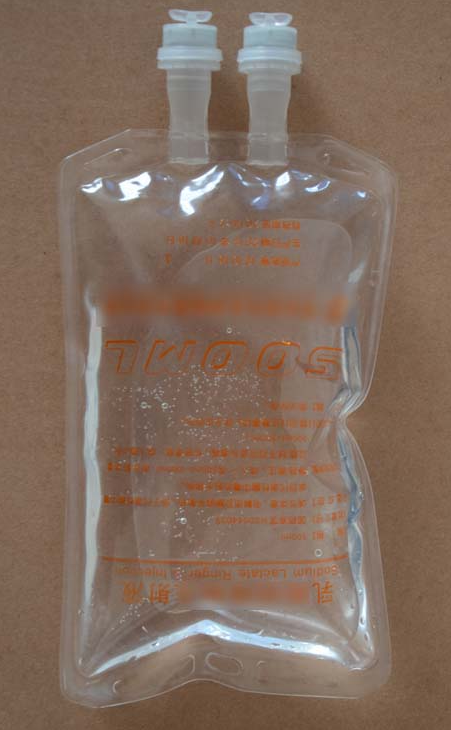

● Samples of Non-PVC Soft Bag With Single Hard Pipe

1. Machine Design and Functions (General Description)

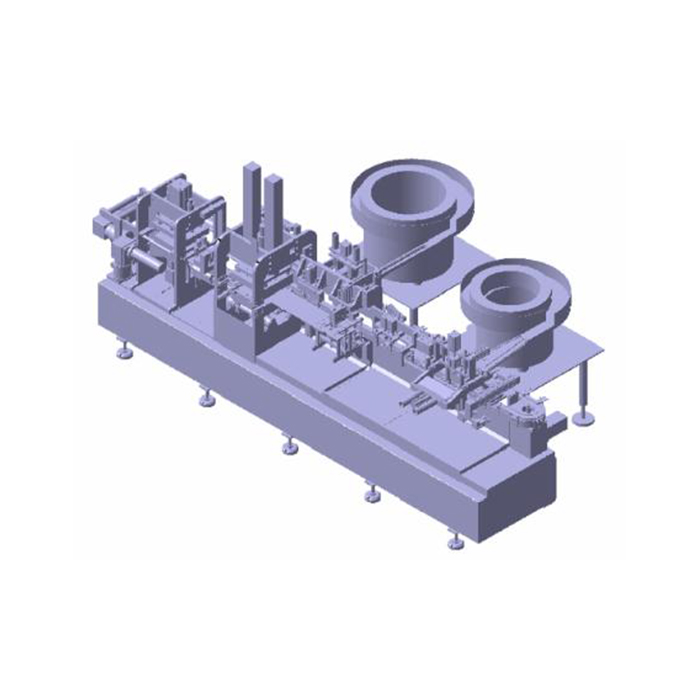

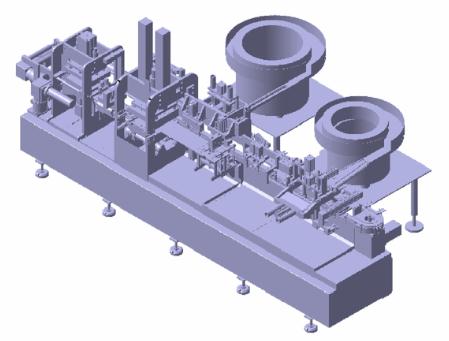

1.1 Axonometric drawing of automatic bag form fill seal line

Protective glass cover and electric control cabinet are not included.

1.2 Advantages of our equipment

-1- Precise temperature control

Temperature error can be controlled within ± 0.5 ℃,Precise temperature control device can be used to ensure that all qualified membrane。

-2- Zero-tolerance manufacturing process

To ensure that mold flatness and parallelism tolerances within the 1% mm,easy-replacement,no-adjustment,no-layer。

-3- Advanced industrial network

System uses advanced communications network,All kinds of industrial equipment connected to the network. Simplifies the hardware connection,Reducing the use of the wrong point,the difficulty of reducing the use and maintenance,reducing the number of workers,Streamlined device structure.

-4- Simple design

Simplicity is the ultimate sophistication.

To ensure that equipment is stable and efficient,at the same time,let the simplest device structure,the easiest operating,debugging and aegis. Reduce the demands for the quality of workers,Reducing the number of workers.

Flexible,easy to organized production.

2. Functions

Statement

The machine is designed for pharmaceutical use according to the GMP and FDA guidelines.

It is designed for forming, filling and sealing two bags, each of them provided with two SFC-

ports per cycle.

2.1 General Description

The machine consists of the following components:

-01- Unwinding station

-02- Printing station

-03- Film transfer station

-04- Contour welding and cutting station

-05- Port pre heating station

-06- Port feeding with feeder bowl and buffer

-07- Port welding station

-08- Waste ejector station

-09- Bag flip & Leak detection station

-10- Filling station

-11- Cap station with feeder bowl and buffer

-12- Bag outfeed with transport belt

2.2 Design Capacity

The machine achieves a potential output of 2500 bags/h with a bag size of 250 ml.

2.3 Labor demand

Two operators are necessary to operate the machine

(1 permanent, second operator only necessary for film change).

2.4 Machine design

Base machine

● The machine is designed as a single-track linear system with a motor actuated film transfer control. In the machine, the film will be transported through grippers.

● According to its required capacity, the machine is either equipped with one working stations.

● The machine's framework consist of stainless steel AISI 304, especially suitable for pharmaceutical use.

● All components coming in touch with the product are made of stainless steel AISI 316 L quality.

● The safety doors and windows mounted on the framework are made of polycarbonate. Thus they correspond to the health and safety regulations and ensure at the same time an optical supervisory control.

● The machine is equipped with a switch cabinet and a control unit. The control units are interconnected via a bus system.

2.5 Working Station

-01- Unwinding station

The film is fed into the machine via a motor controlled unwinding device. The film roll is pneumatically cramped onto the reception bolt. In order to ensure a constant film transfer speed, the film is temporarily stored on a castoring wheel. Thus, the changing film roll diameter is compensated. The motor to unwind the film will be started as soon as the castoring wheel releases a sensor.

※Unique membrane-free alarm,alarm can be exhausted in the membrane.

-02- Printing Station

● The 'Full-Face' print is printed on the bag film using a hot film printing unit.

● Variable manufacturing data, such as the production number, the best-before date, the batch number, etc. are adapted by exchanging the separate reception via which are especially designed for this purpose.

● Printing temperature, printing time and printing pressure are adjustable.

Control precision(±0.5℃).x

● The automatic printing film supervisory unit (odometer to determine the film feed) ensures a machine stop in case the printing film has run out or teared off, and thus ensures a constant bag printing.

● The printing film reception rolls are equipped with a pneumatic, hand-operated clamping. So the printing film can be exchanged very easily and without any special tool, the time required for service purposes is reduced to a minimum.

● In order to ensure that the bag film does not adhere to the printing film subsequent to the printing process, the bag film is held down by pneumatic film clips.

For changing the printing block, only two clamps have to be released. The block reception must not be removed if you have to change the characters of the production and best-before date, the batch number, etc.

-03- Film Transfer with Film Opener

The film transfer is performed by an electric motor driven linear gear unit. During the transfer, the film is held by pneumatic film clips. When the film is fed in, the two film layers are opened with a fixed opener taper key in the front area, where the next step, i.e. the port insertion, will be carried out.

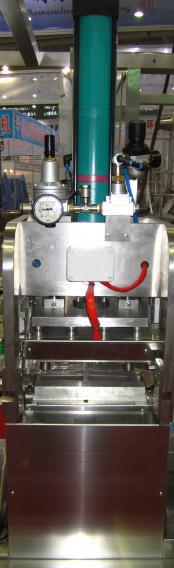

-04- Contour Welding and Cutting Station

This station is used for welding the outer contour of the bag, for adhering the ports to the bag film and for cutting the outer contour of the bags. The welding is done by exchangeable welding tools provided with heating cartridges to produce the required welding temperature.

Welding time, pressure and temperature are adjustable.

Control precision(±0.5℃).

The welding temperature is verified within a defined min./max. range by the PLC control unit and temperature sensor, in order to ensure a permanently correct welding process.

In case the welding temperature remains under or exceeds – for any reason whatsoever – the defined min. / max, range, the machine will stop. Simultaneously, an error message is displayed in the control panel.

※ Using the unique design of the heating plate and mold separation, replacement of mold is extremely simple.

※High-precision processing technology, don't adjust the mold.

-05- Port Pre Heating Station

This station serves for pre-heating the ports up to a certain temperature before they arrive between the two bag film layers of the contour welding station, and thus it ensures an optimal welding of port and bag film. For this, two pre-heating tools which are pre-heated to a certain temperature and having the same contour as the ports, are brought together on the port. Pre-heating temperature and time can be adjusted via the control panel.

※Using the unique design of the heating plate and mold separation, replacement of mold is extremely simple.

-06- Port Feeding with Feeder Bowl and Buffer

The port conveyor belt is fed with the ports via feeder bowl, buffer and linear transfer. Grippers place the ports into the port of the conveyor belts and the servomotor and gear driven conveyor belt transports the ports stepwise towards the particular stations.

-07- Port Welding Station

This station is used for welding ports and bag film.

For this, two welding tools which are preheated up to a certain temperature are brought together on the bag head contour.

Welding time and temperature are adjustable via control panel.

Control precision(±0.5℃).

Using the unique design of the heating plate and mold separation, replacement of mold is extremely simple.x

High-precision processing technology, perfect welding.

-08- Waste Ejector

This station serves for removing the film rests that still adhere to the different bags.

The film rests are gripped by the pneumatic grippers and transported towards the waste box by a pneumatic driving mechanism.

-09- Bag Flip & Leak Detection Station

Holding an empty bag of the fixture to be pulled down,by suction vacuum bags leak detection method.

※Leak bag or no bag will not fill.

This servomotor and gear driven bag conveyor belt transports the bags cycle-wise towards the different working stations.

-10- Filling Station

The filling station is equipped with 2 filling systems. The filling systems are lowered towards the bag by means of a pneumatic cylinder. The filling systems consist of a filling valve, a flow meter, product distribution and connecting hoses. For proportioning the filling volume a mass flow metering system is used. The filling systems, flow meters, product distribution and product lines are designed to be sterilized inline.

-11- Cap Station with Feeder Bowl and Buffer

The cap station is fed simultaneously with two caps via buffer, feeder bowl and linear transfer. The caps are fed into a nid located directly over the bag. Here, the caps which are held through a vacuum, are welded on the port. Thus, the bags are form closed with the cap.

※ Caps prior to the picking up first by the cylinder compaction,ensure that smoking will not fall from the film ignited by heat. Reduce the heat to of maintenance.

※ Use a heating piece of complete and the melting of the hermetic seal docking port and welding,reduce the heat to of maintenance.x

-12- Bag Outfeed with Transport Belt

The finished bags are taken out by gripper system and leave the machine to the outfeed

conveyor belt.

Remarks:with are unique of our company.

3. CIP and SIP

The CIP/SIP units of the machine can be ordered optionally.

It is consisting of automatic function of CIP / SIP including steaming bar and drain pipes for condensate water. The outlet valves of drain and steam are to open manually.

● CIP(Clean in Place)

After the rinsing process has been started from the filling station control panel by manual operating, the filling nozzle will move downward into the cleaning and steaming bar. The filling nozzle at the different filling locations are sealed with a silicone gasket in the cleaning and steaming bar. The cleaning fluid flows from the product connection through the surge tank into the product distributor. From here, the cleaning fluid flows into the different filling locations, through the mass flow, the product tube and through the filling valve into the cleaning and steaming bar. From here, the cleaning fluid flows through two outlet tubes into a drainpipe beneath the filling station. After cleaning, the filling nozzle returns to its original position.

● SIP(Steam in Place)

After the cleaning of the machine the steaming process will begin at a temperature of about 125 °C. After the steaming process has been started from the filling station control panel by manual operating, the filling nozzle will move downwards into the cleaning and steaming bar. The filling nozzle at the different filling locations are sealed with a silicone gasket in the cleaning and steaming bar. The filling valves are opened and the superheated steam moves from the product connection trough the surge tank into the product distributor. From here the superheated steam moves into the different filling locations, through the mass flow, the product tube and through the filling valve into the cleaning and steaming bar. Inside the cleaning and steaming bar, two side-mounted temperature probes (PT - 100) monitor the temperature during the cleaning process. From here, the superheated steam moves through two outlet tubes into the drainpipe beneath the filling station. Two stop valves are located on the left and on the right hand side of the drainpipe. Beneath stop valve a approx.1 mm diameter aperture is located. Through this gooseneck the superheated steam condenses into water. This condensate is finally let out through a drainpipe. At the end of SIP process the filling nozzles will stay in the sterile steaming bar and wait for set up or next production to ensure sterile conditions of the whole filling system.

4. Technical Parameters

The basic data instruction for soft bags and materials

| MATERIALS | |

| FILM | PP double wound multilayer flat film (3 layers/5 layers) confirms to production requirements |

| For roller parameters, pls refer to the agreed standard product drawing for roller parameters. | |

| PORT | Transfusion polypropylene composite covers confirm to prodution requirements. |

| For tube form and parameters, pls refer to the agreed standard product drawing. | |

| sealed by heating welding method. | |

| PRINTING | Hot Foil printing. |

| For size and colour tape, pls refer to the agreed standard product drawing. | |

| Printing plates are not involved. | |

| Printing plate mounting holes are based on the customer's requirements. | |

| SOFT BAGS | |

| SPECIFICATION | 50/100ml(130mmx120mm); 250 ml(130mmx160mm); |

| 500 ml(130mmx220mm);1000 ml(130mmx260mm) | |

| Please subject to the agreed specification and dimensions on the drawing. | |

● Equipments basic description

| Machine Dimension | |||||||

| Equipments specification | (Max. mm) | (Max. mm) | (Max. mm) | Remarks | |||

| Length | Width | Heigth | |||||

| (Max. Mm) | (Max. Mm) | (Max. Mm) | |||||

| KM2 Type | 4350 | 1900 | 1800 | 2bags/group | |||

| (including roller's length ) | (with protective cover) | (with protective cover) | |||||

| Equipments Capability | |||||||

| Soft | KM2 type (2 bags/group) | Remarks | |||||

| bags type | |||||||

| 50/100ml | 2500 bags/hour | Filling pressure : 0.40Mpa | |||||

| Air compressure : 0.75Mpa | |||||||

| The data needs to meet the following conditions : | |||||||

| 500ml | 2400 bags/hour | Filing pressure 0.40Mpa | |||||

| 1000ml | 1800 bags/hour | Conpressed air 0.75Mpa | |||||

| Filling | |||||||

| Filling pressure | 0.2Mpa-0.4Mpa | ||||||

| Filling tempreture | Max.55° C | ||||||

| Filling accuracy | +/- 1.0 % | ||||||

| Product connection | 50.5 standard Tri-Clamp | ||||||

| Online disinfection | Max.125° C CIP | ||||||

| Standard equipment only provides the disinfection for pipeline interface components. | |||||||

| Pass Rate | |||||||

| Pass Rate | Min. 99.9% (based on the qualified materials and non error operation) | ||||||

| Leakage rate Max.0.001% | |||||||

| Waste | 99.99%, with seperate waste angel collection tank | ||||||

| angel rejection rate | |||||||

| Energy demand | |||||||

| Power | 3Phases 380V 50Hz | ||||||

| KM2 model : Max. 10kw | |||||||

| Conpressed Air | 0.5Mpa~0.75Mpa,with dry oilless compressed air | ||||||

| KM2 model, about 1500L/min | |||||||

| Cooling Water | Null(Cooling module can be increased according to customer requirements) | ||||||

| Working Environment | |||||||

| Room Tempreture | 20 °C – 24 °C (suggested) | ||||||

| Air Humidity | 45%-65%(suggested) | ||||||

| Max.85% | |||||||

| Other Parameters | |||||||

| Temperature Control Accuracy | Stable Running Tempreture Control Accuracy +/- 0.5° C | ||||||

| The Start-Stop control accuracy +/- 1.5° C | |||||||

| (Bag-making molds/ Port welding molds/ Port preheating molds) | |||||||

| Cap welding error | Max.0.1mm | ||||||

| Noise | Max. 75dB | ||||||

| Operator | Fixed operator : 1 person | ||||||

| Auxiliary operator : 1~2 persons (to replace production materials) | |||||||

| Language | English | ||||||

5. Key Parts and Components List

● All contact parts with non-PVC bags are SUS304.

● All contact parts with I.V. liquid drug are SUS316L.

● All filling valve membrane and rubber tubes made of silicone rubber HV.

● Other parts are as follows.

| Name | Brand and Origin | Remarks |

| main parts | China | The raw materials all meet FDA standard and GMP standard, with high quality stainless steel, and mold steel and silicone rubber. |

| electronic | Beckhoff from Germany | Including human-machine-interface, servo controlling system, servo motor and other parts |

| controlling system | ||

| temperature controlling system | Beckhoff from Germany | |

| pneumatic system | Festo from Germany | Including general cylinder、valve terminal、main pneumatic parts |

| electric elements | Schneider、OMRON、Phoenix,etc | Circuit breaker、relay、switch、terminal, etc. |

| booster cylinder | Tox from Germany | Used for welding working station around the soft bag |

| magnetic switch | Turck from Germany | Or other similar brand |

| sensitive optical | KEYENCE from Japan | |

| fiber sensor | ||

| proximity switch | Festo from Germany | |

| other main | MISUMI from Japan | Including straight line slide system, buffer, elastic gasket, etc. |

| mechanic parts | ||

| other parts | from all famous brands both domestic and imported. | |

| other components | All stainless steel components which contact with the primary package | |

| are made by: | ||

| GMP standard high quality 304L stainless steel | ||

| All components which contact with materials are made by: | ||

| GMP standard high quality 316L stainless steel | ||

| Filling valve membrane, rubber tube and sealing ring are all made by: | ||

| GMP standard high quality Silicone rubber HV | ||

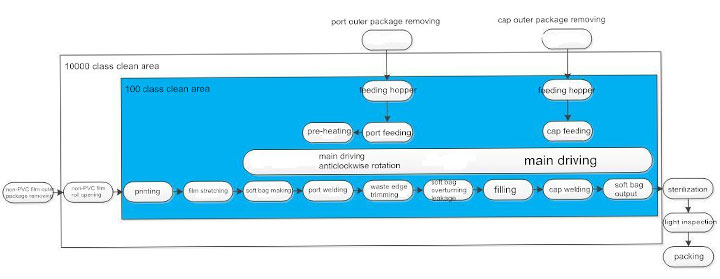

6. Process Flow Diagram

ketchup production line

ketchup production line

Acceptance inspection--Russian Client

Acceptance inspection--Russian Client

2011 FCE

2011 FCE