Pre-filled Syringe Filling and Plugging Machine

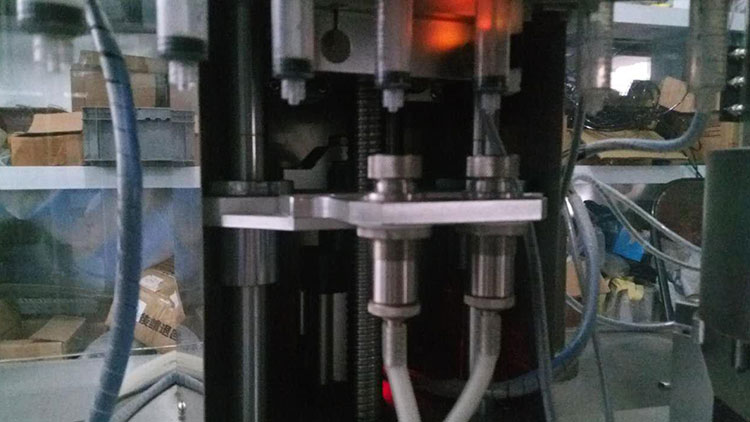

Main machine uses double head restoration to prevent the plunger not being pressed to the bottom of the syringe, see below picture

● Detail Photos of Machine

● Detailed introduction of machine

1. Main machine uses double head restoration to prevent the plunger not being pressed to the bottom of the syringe, see below picture

2. Double filling heads, and double heads lifting, it can meet the production 30-50pcs/min, with high cost performance. Filling volume is digital adjusted, it can be set on touch screen.

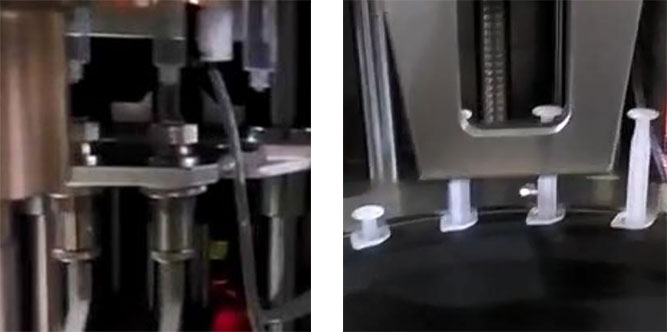

3. Filling mouth sealing is with buffering device, can prevent leakage, see below picture.

4. Main machine adopts double heads locking mouth, screw rotary has torque setting, and can also adopt press in method.

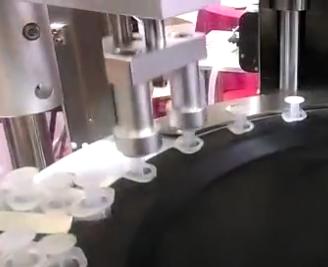

5. Plastic stopper also have automatic collection and feeding function, it will be automatically pressed in after positioning. (see below pictures)

6. Main machine adopts closed structure with 4 transparent bifold doors.

7. Main electrics: PLC is from Panasonic, other touch screen are mostly adopts Schneider products.

8. photoelectric detection,cylinder solenoid valve and other elements are allocated based on highest configuration( mainly uses Omron and Airtec products)

● Technical Parameter

| 1 | Filling Volume | 1ml |

| 2 | Number of Filling Head | 2 Sets |

| 3 | Capacity | About 30-50 PCS/Min |

| 4 | Sealing method | Screw or Pressure |

| 5 | Supply Power | 3P 380/220V 50-60HZ 4.0KW |

| 6 | Compressed Air | 3-5kg/cm2 0.15m3/min |

| 7 | Machine Dimension | 1400*1150*1800mm(L*W*H) |

| 8 | Overall dimension(including Laminar Flow) | 1400*1150*2170mm(L*W*H) |

| 9 | Net Weight | About 1000Kg |

● Machine Structure

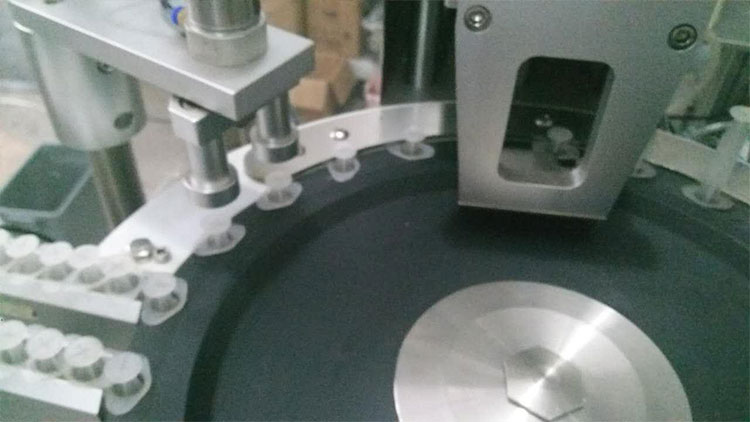

♢ It adopts star wheel type intermittent motion conveying the syringes, with the upper and lower orientation, circle orientation, with fault protection clutch.

♢ With two filling heads, besides filling accuracy control, syringe barrel and plunger stretch synchronously, try to avoid bubbles.

♢ The rubber tip is feeding through vibrating bowl, with small star wheel synchronous orientation rubber tip press.

● Main Materials

♢ Conveying soft pipe: Silicon rubber soft pipe, meets EVA、FDA requirements;

♢ Contact parts with liquid is SUS316L / Ceramic/ Silicon gel

♢ Piston cylinder: High purification Silicon dioxide

♢ Machine frame: vertical shaft and table: SS304, outer surrounding: transparent acrylic

♢ Other parts are SS304(0Gr18Ni9Ti)or SS321(1Gr18Ni9Ti), or Aluminum alloy

ketchup production line

ketchup production line

Acceptance inspection--Russian Client

Acceptance inspection--Russian Client

2011 FCE

2011 FCE