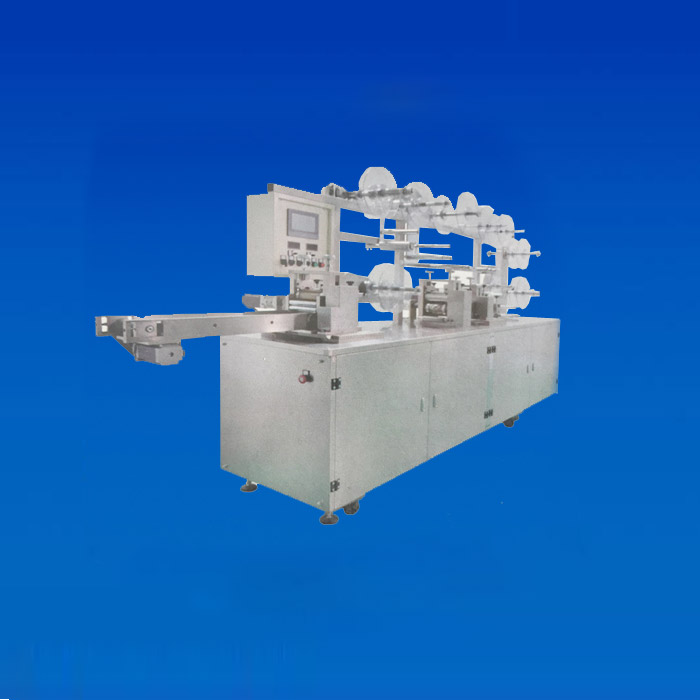

Bottleneck Patch Machine

Hobbing bottleneck patch machine, designed and manufactured by us, adopts new technique, new workmanship and electromechanical integrative design.

1. Introduction:

Hobbing bottleneck patch machine, designed and manufactured by us, adopts new technique, new workmanship and electromechanical integrative design. It breaks through the shackles of traditional equipment with full hobbing workmanship, which makes the production speed reach 800 patches per minute.

2. Production workmanship procedures

PLC control, touch screen operation, and completing from uncoiling---adhesive plaster peeling---adding absorbent pad(∮16mm)---covering with release paper---bottleneck patch positioning hobbing (∮28mm semi-cutting)---product contiguous cutting off (hobbing)---conveyor contiguous bottleneck patch counting step-by-step output.

3. Equipment use:

Suitable for producing bottleneck patches.

4. Scope of application:

Suitable for base materials of PE adhesive tape, PU adhesive tape and so on.

5. Brief description of main technical parameters and structure:

| Model | PKTJ-1 |

| Max diameter of material coil | 380mm |

| Max width of adhesive tape | 90mm |

| Absorbent wool | ∮16mm |

| Bottleneck patch shape | ∮28mm |

| Quantity | Four patches |

| Feeding device | Servo drive |

| Speed | 0-800 patches/min |

| Uncoil tension | Magnetic powder tension control |

| Conveyor | Step-by-step, counting conveying |

| Machine power | 4KW |

| Power source | 380V |

| Overall dimension | 3800*700*1900mm |

ketchup production line

ketchup production line

Acceptance inspection--Russian Client

Acceptance inspection--Russian Client

2011 FCE

2011 FCE