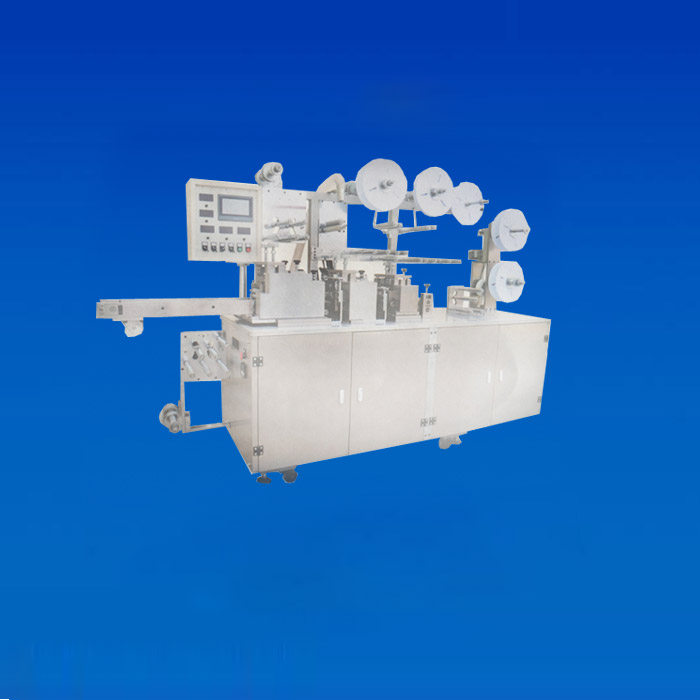

Hobbing Band-aid Packaging Machine

Hobbing band-aid packaging machine is a dedicated device specially designed and manufactured for hygienic material manufacturers by Shanghai Daye Packaging Machinery Factory, which is used for manufacturing band-aids.

Samples of products

1. Introduction:

Hobbing band-aid packaging machine is a dedicated device specially designed and manufactured for hygienic material manufacturers by Shanghai Daye Packaging Machinery Factory, which is used for manufacturing band-aids.

To satisfy different requirements of manufacturers for processing band-aid, our company has manufactured two models of hobbing band-aid packaging machines, namely, GQCBJ-2 and GQCBJ-3.

Electromechanical-pneumatic integrative design, touch screen operation, and PLC control.

2. Production workmanship:

Uncoiling---adhesive plaster peeling---adding absorbent pad---covering with release paper---band-aid hobbing---band-aid packaging---packaging bag dotted line hobbing---packaging bag contiguous (rolling) cutting---contiguous band-aids counting, step-by-step---manual box packing.

3. Equipment use:

Suitable for band-aids of various specifications.

4. Scope of application:

Suitable for base materials of non-woven fabrics, breathable PE adhesive tape, PU adhesive tape and so on.

5. Brief description of main technical parameters and structure:

| Model | GQCBJ-2 | GQCBJ-3 |

| Max diameter of material coil | 380mm | 380mm |

| Max width of adhesive tape | 85mm | 85mm |

| Max width of band-aid | 78mm | 78mm |

| Cartoon positioning | Color code tracing | None |

| Max width of packaging | 100mm | 100mm |

| Feeding device | Servo drive | Servo drive |

| Packaging speed | 0—1000p/min | 0—720p/min |

| Packaging positioning | Color code tracing | None |

| Uncoil tension | Magnetic powder tension control | Magnetic powder tension control |

| Conveyor | Step-by-step, counting conveying | Step-by-step, counting conveying |

| Machine power | 4.5KW | 3.5KW |

| Power source | 380V | 380V |

| Overall dimension | 2800*750*1900mm | 2800*750*1900mm |

The equipment could be supplemented with heat-sealing packaging device as required.

ketchup production line

ketchup production line

Acceptance inspection--Russian Client

Acceptance inspection--Russian Client

2011 FCE

2011 FCE