YWJ250-II Softgel Encapsulation Machine

Water-bath Injector, the temperature fluctuated in +/-0.1℃, save 14% gelatin; improve 1.5% rate of finished products; and save the maintained cost and time.

Samples of Softgels

● Feature of the Machine

1. Water-bath Injector, the temperature fluctuated in +/-0.1℃, save 14% gelatin; improve 1.5% rate of finished products; and save the maintained cost and time.

2. Computer control the plunger pump, improve the precision of medicine injection volume, and save more medicine and material cost.

3. The holes of the left and right main axis are processed with extreme accuracy on the boring machine imported from Switzerland. Though the mould roll has been extended in length, can be keep high coaxial degree that guarantees the smooth seam and finished product rate of the softgel capsule.

4. Bigger cam drive plunger pump, can provide stronger to plunger pump. That make the machine can inject widely high viscosity of raw material, such as Suspension, Propolis (Bee glue), Soft phospholipids, Liquid calcium and Herbal suspension.

5. Friendly human-computer interface, easy to operated. The simulated running of machine. The data can be set via touch screem, and easy to realizes network monitoring, statistics and reports output. All electric parts use world brand parts, such as Siemens, Schneider.

6. The touch screen provides professional " recipe" function that can save the production paramters and recall them by one key.

7. The micro-lubrication device, can be adjust lubrication volume in fine volume, save cost.

8. Pneumatic clamping system makes capsule filling process more simple and reliable.

9. Motor hoisting injector can be fine located position as requirement, and reduce the workload of operator.

10. Speed of each gelatin film drum and main axis can be adjusted respectively by respectively inverter; that is controlled by operator according to actually requirement.

11. The opening of gelatin box is controlled accurately, the gauge showed gelatin film thickness. Easy to control the thickness.

12. Automatic controlled water-cooling system is adopted for the cooling of gelatin film, which is more safety and more reliable.

13. Air-cooling system is adopted at the output of softgel capsule, that make softgel capsule more beautiful.

14. Insulation hopper, can keep medicine temperature steady, more suit to fill suspension into the softgel capsules.

● Main Technical Data

| Mould Size (mm) | Dia. 150 X W: 250 |

| Mould Revolution: (RPM) | 0-5 Rpm (adjusted variable speed) |

| Volume of Plunger Pump | 0-2 ml (adjustable continuously) |

| Pump Accuracy: | +/- 1.5%; |

| (Filling the Suspension & smaller filling volume) | |

| +/-0.5% | |

| (filling volume not less than 500 mg) | |

| Pump Type | 20 plunger pump |

| Production Capacity : | maximum 58800 capsules |

| (20# oblong size capsule) | per hour hour |

| Power Supply: | 12 Kw, 360V 3 phases (can be modified as user's requirement.) |

| Weight: | 1,500 Kgs |

| Machine Dimension: (LxWxH, mm) | 2040x960x1900 |

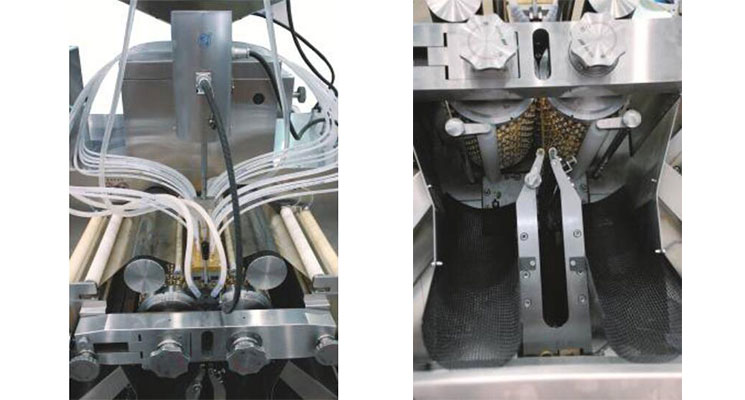

● Photo of YWJ250-II Automatic Softgel Encapsulation Machine

|  |

electric parts use Siemens and Schneider | |

| |

Water-bath injector keep production efficient | high precision mould, net gelatin cooling system |

|

Thickness Gauge easy to control gelatin film thickness |

ketchup production line

ketchup production line

Acceptance inspection--Russian Client

Acceptance inspection--Russian Client

2011 FCE

2011 FCE