Newly developed straight-line suppository filling and sealing machine for PVC suppository.

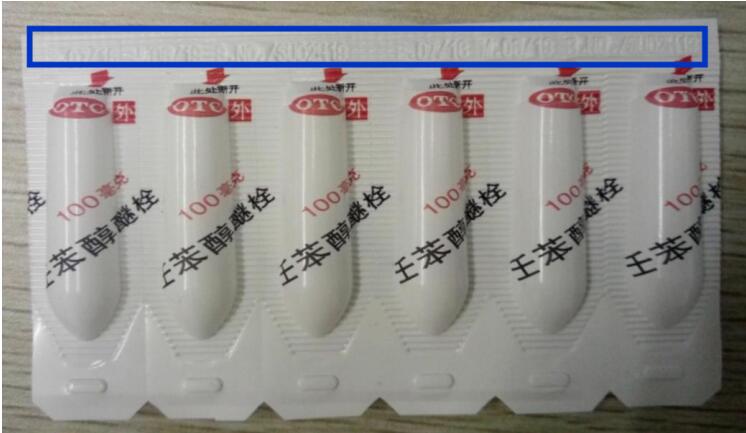

l Suppository Samples

u Priting Introduction

1. Normally our final suppository product is already with

steel seal printing (it also means carving printing)

lot no., Mfg & Exp will be during sealing, just like the following photo:

u Technical Parameters

Output/hour |

10000-13000 pcs/hour (center distance 17.4mm) |

Single dosage | 0.5—5ml |

Dosage allowed

| <±2%

|

Applicable suppository form

| Bullet form, torpedo form,duck-mouth form and other special form. |

Adapt to the material

| Synthetic fatty acid glycerides, glycerinated gelatin, polyethylene glycol, etc. |

Homomixer | 50L |

Atmospheric pressure | 0.6Mpa |

Atmospheric pressure

| 0.6m3/min |

Water quantity/hour | 50kg (Cycle using)

|

Working voltage | 3-Phase AC

|

Total power | 16KW |

External dimension | 4500mmx2200mmx2000mm |

Packaging Film | PVC/PE laminated film |

Total weight | 1200kg |

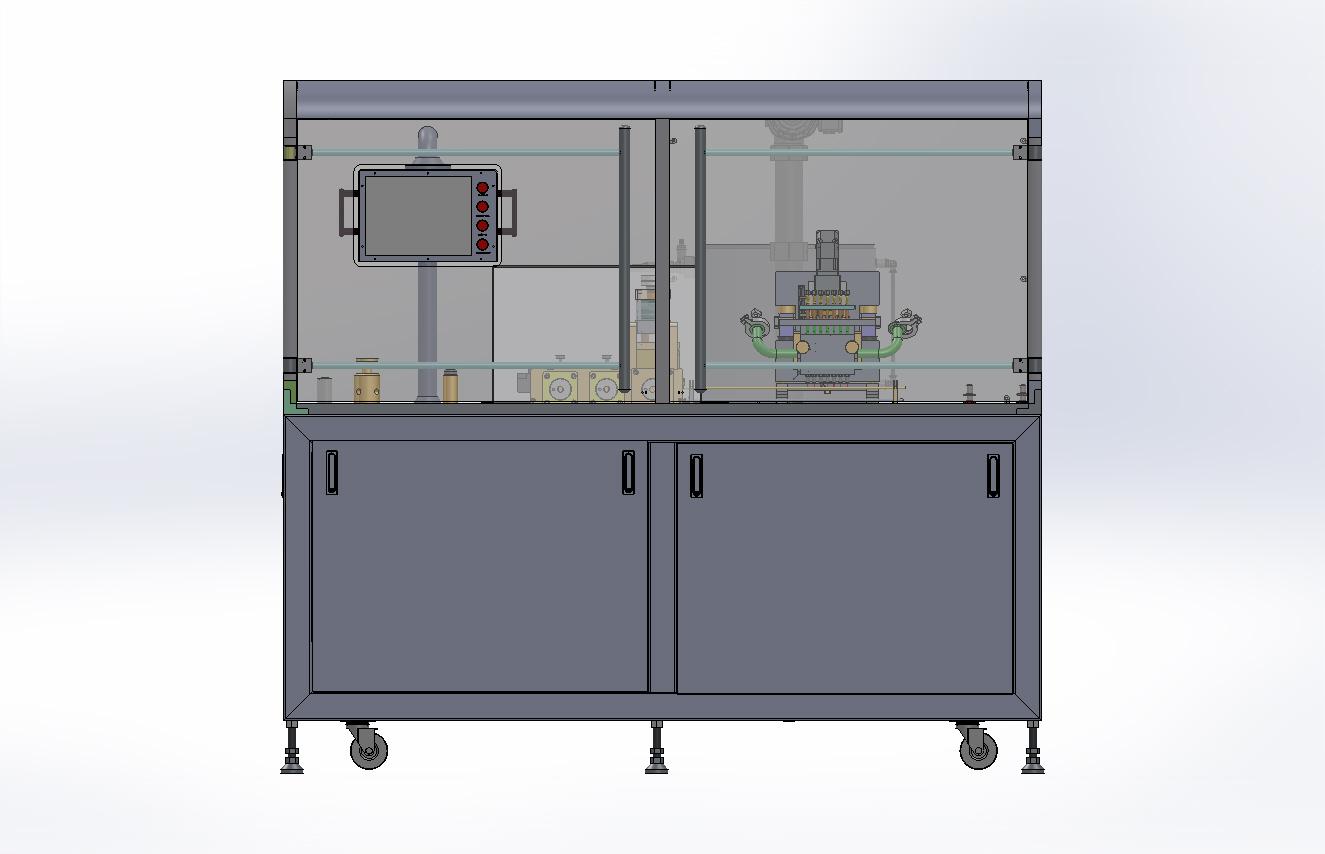

u Whole Machine Operating Principle

1. Forming part:

Film material on the film s plate(PVC/PE)through the gripping agencies into forming area to preheating film——>forming mold——>blowing film——>blown film forming triangle knife cut edge technology,the dotted line cut.

2. Filling part:

Seven nozzles filling,for forming suppository one time embedded filling,filling precision ± 2%,material barrel with electric-heating insulation system,top with a stirring motor so that drug keep uniform state,the drug in the barrel through cycle pump into filling nozzles,one time filling the remaining drug cycle through the other end of a raw material barrel to do the next filling.

3. Cooling part

Filling the entire row of drug finished then into cooling frame,cooling box internal with chiller block,cooling wind through four condensers in the cooling box to cooling suppository on the cooling rack.

4. Seal tail and type code

Servo driving, accurate transfer position, to realize continuous shear,

(for example: 1/2/3/4/5/6/7/8/9/10, any adjustment in touch screen. )

u Different Parts Description

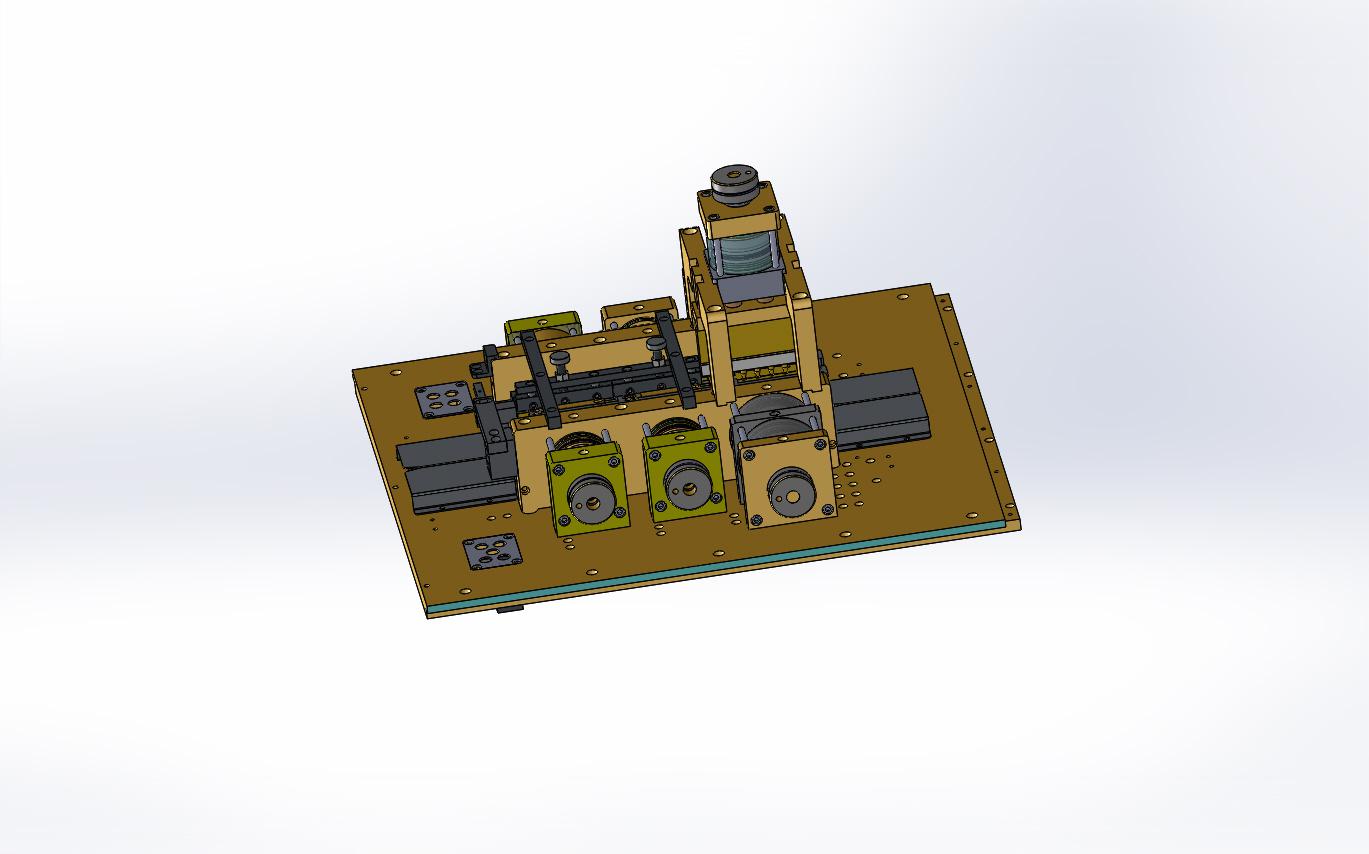

1. forming part

Through the film putting plate, servo transmission clamp, forming, trimming, filling pump, material barrel, material circulating pump station composition, to complete

the suppository shell thermoforming, filling process, etc. (picture 6-1)

(picture 6-1) schematic diagram of forming and filling part

1.1 forming

The packing material PVC/PE is put to A、B film putting plate (picture 6-2), through the guide wheel, servo film feed clamping mechanism(picture 6-3), to enter the molding station. The station has preheating, heating, butt joint blowing and forming mould(picture 6-4), others, the slot is equipped with a corresponding butt blow mold (blow mold) for production use(picture 6-2), the bottom of the frame is provided with a roller and its footing, easy to move and position. Film feeding position is controlled by servo motor, to complete the whole process within the touch screen, with easy operation.

PVC/PE/ A、B Film Putting Plate

Schematic Diagram of Servo Film Feeding and Clamping Mechanism

(Picture 6-2) Molding Diagram

(Picture 6-5) Butt Joint Blowing and Forming Mould

PVC production

The smooth preheating mould is in the first clamp position.

The heating mould is in the second clamp position.

The forming mould is in the third clamp position.

The butt joint blowing and forming mould is in the fourth clamp position.

The butt joint blowing and forming mould and forming mould are vertical.

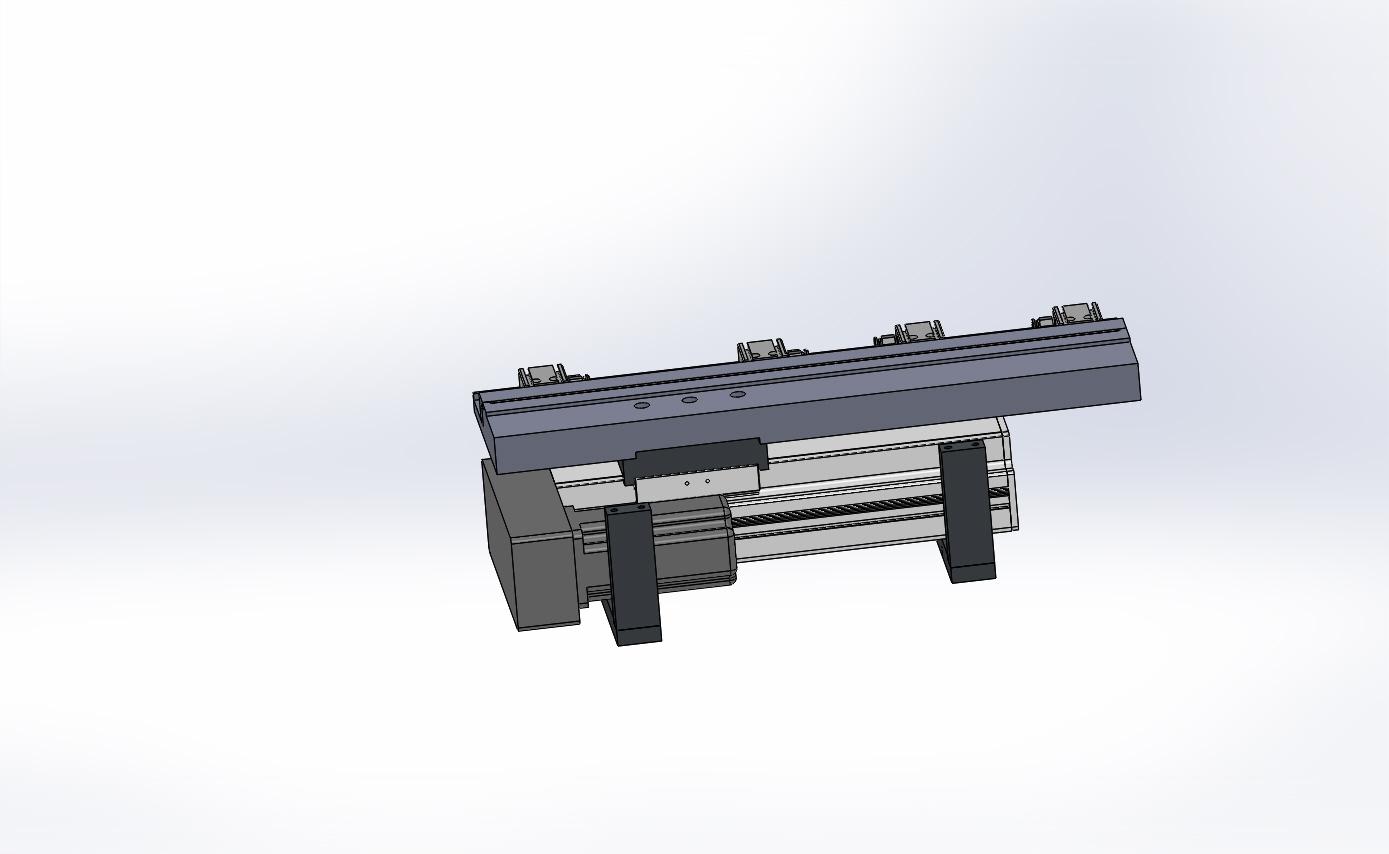

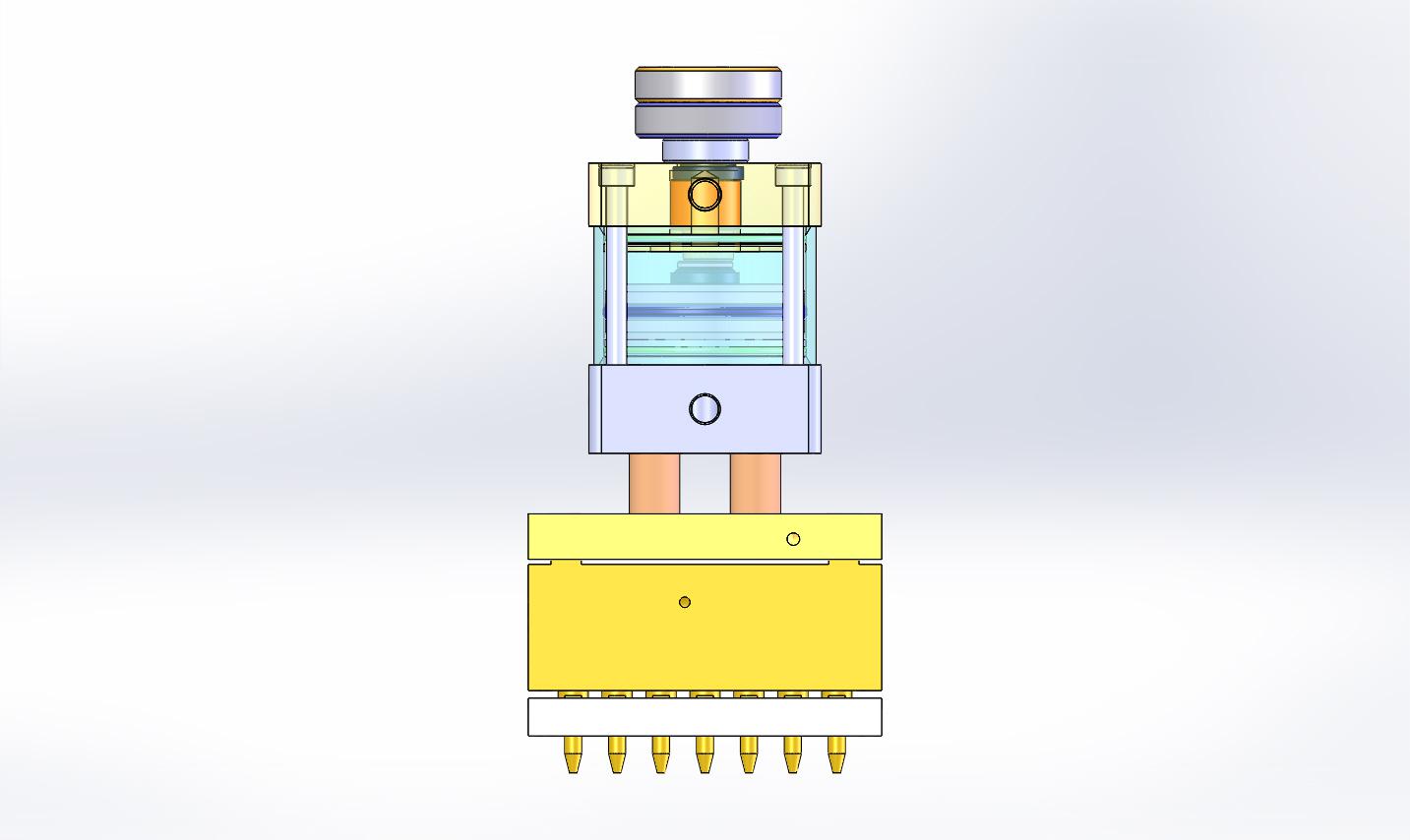

1.2 Filling

The forming suppository shell is getting into the filling station.

The filling process is composed of track, servo screw system, filling pump,

heat preservation material bucket, stirrer, electric heating system,

screw circulating pump and material circulating pipeline, to complete filling process.

When filling, it adopts servo screw system, to ensure accurate and stable filling volume. Filling volume adjustment is completed in the touch screen, simple operation and accurate control.

Diagram of Servo Filling Pump

The filling pump body has 7 plunger pumps, the filling volume is controlled by a servo screw system at the top, the bolt shell enters the injection channel at the lower part of the pump body to fill 7 grains at a time. (picture 6-6).

To add material into the material bucket, the heating element keeps it at a certain temperature, the mixer is adjustable by frequency conversion driven by reduction motor, material circulation pump is composed of screw pump (variable frequency adjustable) and pipeline,speed adjustment is easy to operate in touch screen.

Schematic Diagram of Material Bucket, Stirrer, Circulation Pump

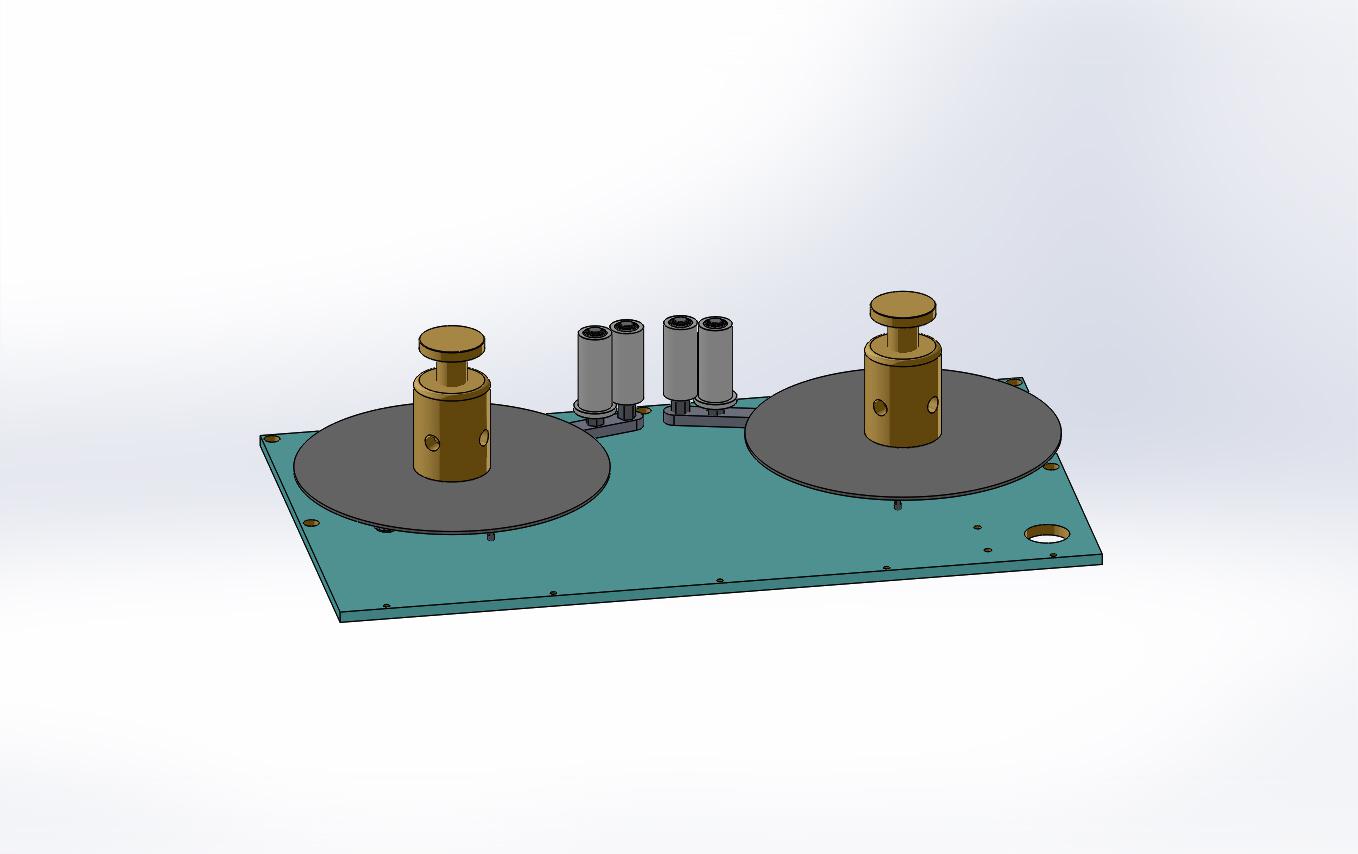

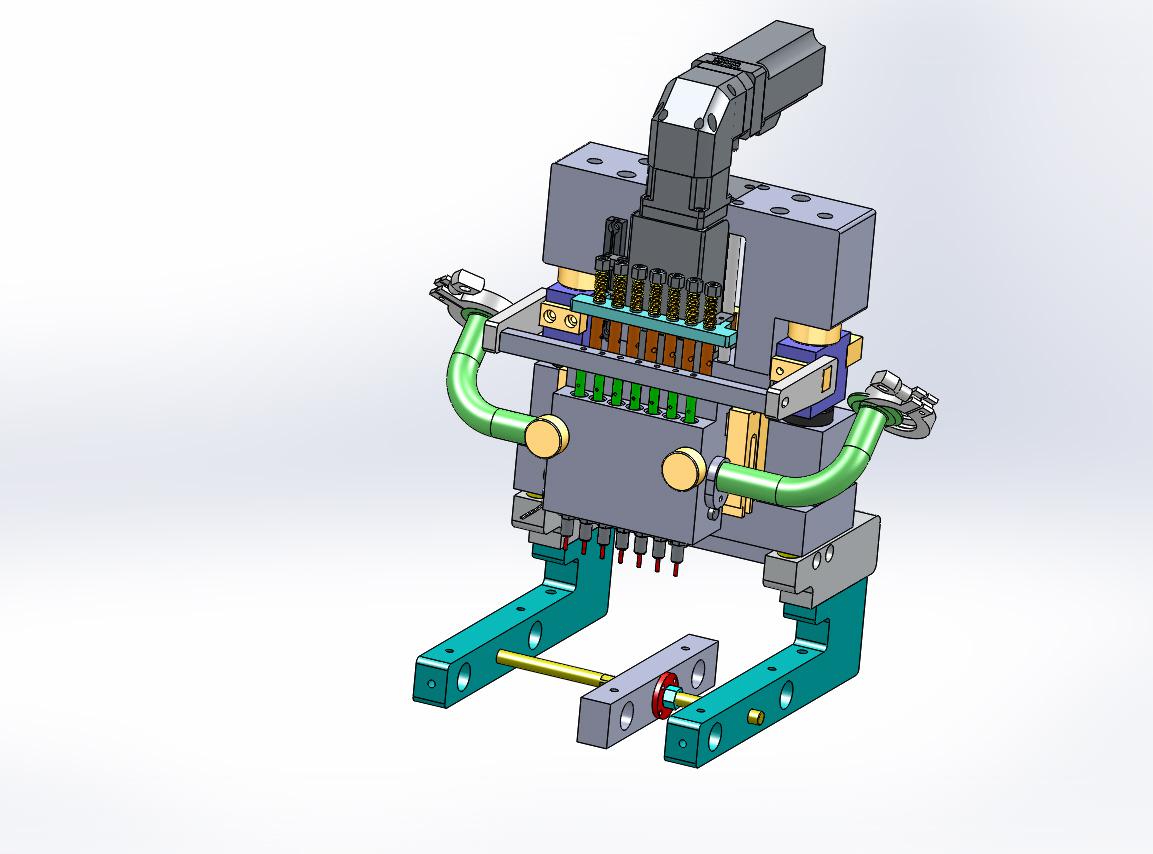

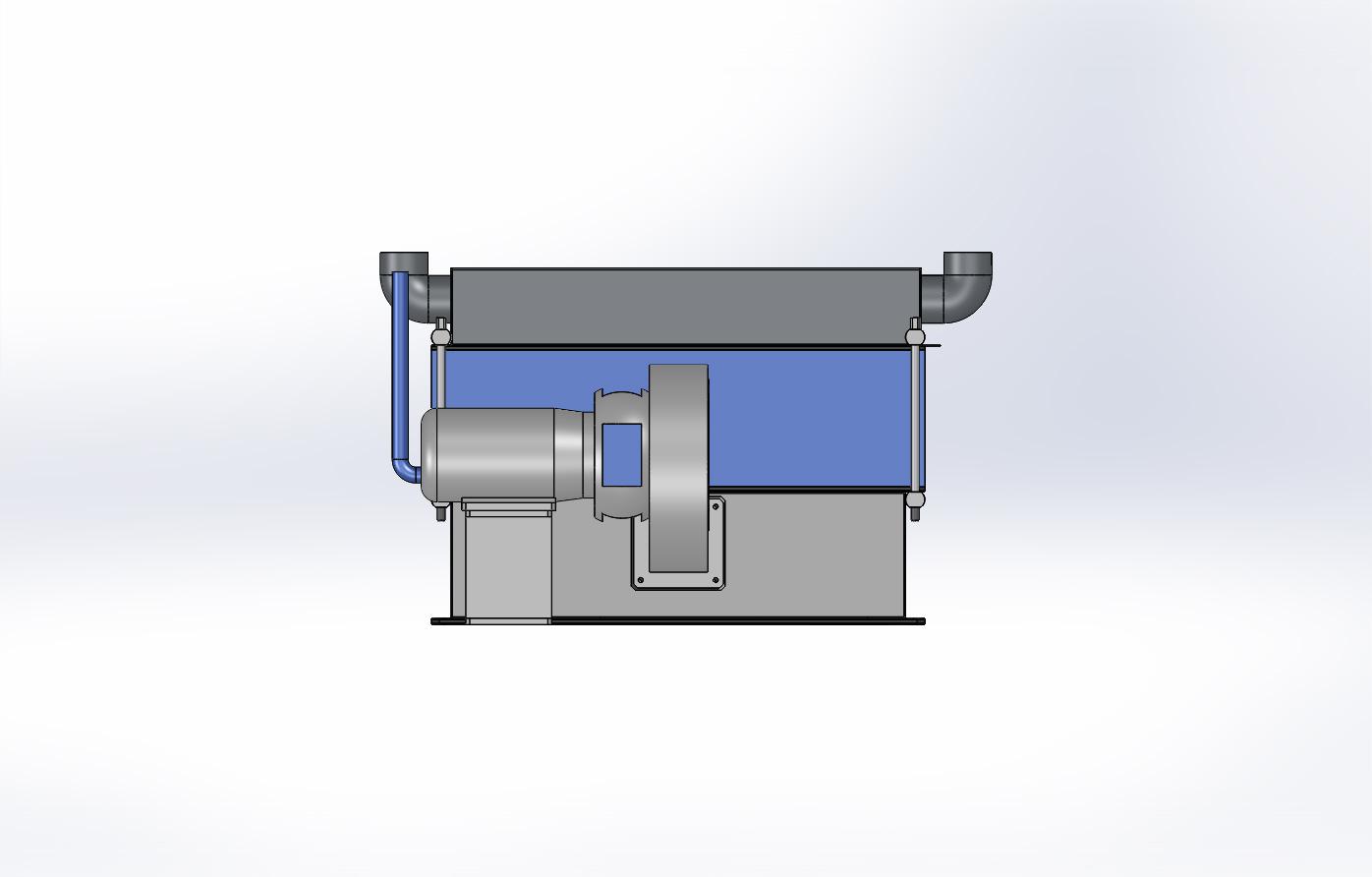

2.Cooling Box Section

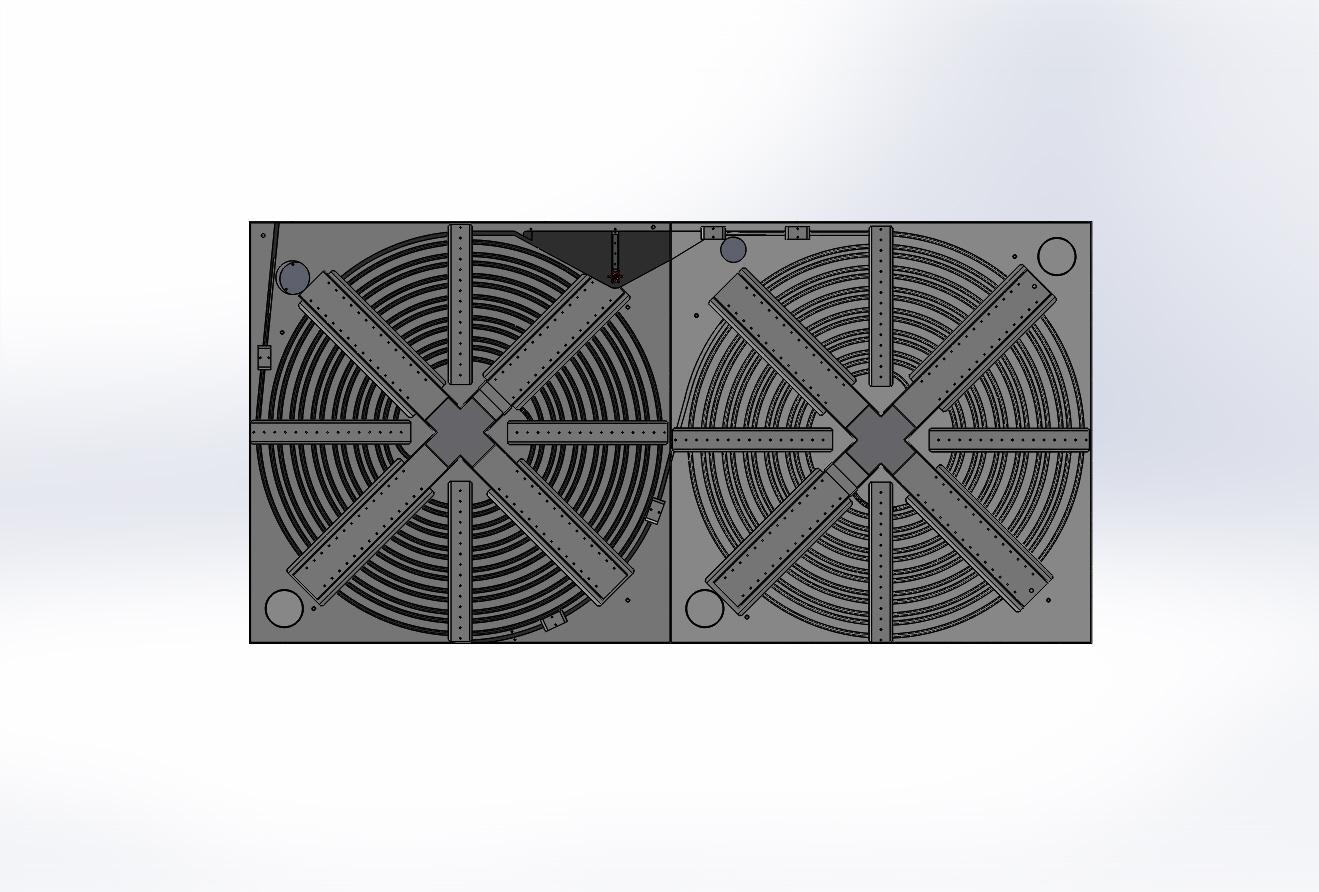

Schematic Diagram of Cooling Box (Picture 6-8)

It is composed of two sets of plate chain transmission system (picture 6-9), film guiding system, drive holding system, cold water pipeline, heat-insulation system and cool exchanger, After filling, to through the plate inside chain conveying completely, 1#plate continuously get into 2#plate.

Between 1#plate and 2# plate, it is equipped with transition device,

to prevent the stacking and breaking between 1#plate and 2# plate.

then to complete the curing process. The cooling temperature selected

by the material is different with different freezing characteristics, by adjusting the cooling temperature of the two cooling disks respectively,(variable frequency adjustable) (picture 6-10), to achieve the required curing requirements. The frame is provided with roller and foot, easy to shift and position. Parameter setting is completed in the touch screen.

After filling the bolt shell into the cooling track, the chain is continuously sent to the end sealing station after cooling, the chain is continuously sent to the end sealing station after cooling.(picture 6-11)

(picture 6-9) Cooling Disc Diagram

Cold water is supplied by a chiller, evenly dispersed by the cold exchanger,the temperature is controlled at 8℃ ~ 16℃.

(Picture 6-10) Schematic Diagram of the Cold Exchanger

Schematic Diagram of Completion of Sealing

3. Seal Parts

After curing, the strip is equipped with sealing servo transmission mechanism, feeding channel mechanism, continuously enter mold preheating, sealing and batch number mould, for batch number printing, for batch number according to the user's needs to change the word code, to trim the bottom and middle lines , to finish the top edge, finally, the servo film feeding plate is fed into the scissors, and the scissors are finally cut into the suppository product.To enter the discharge port into the next process. The number of suppository shells is set in the touch screen, setting freely, with simple operation.

4. touch screen

The touch screen is 10 inch from Siemens, PLC is also from Siemens.

The words in the touch screen is very clear, quality is very reliable.

All parameters are completed inside the touch screen,

To change the mould, then changing the variety of suppository mould is very simple.

All alarms are displayed on the main control screen,

with convenient maintenance.

u Equipment Advantage

1.PLC inspection function:

through PLC online monitoring function can inspect

automatic running fault and alarm as the same time show the reason of running fault its convenient operator to remove the fault timely.

2 .The filling part with removing static electricity system:

Note:before forming shell reach filling place if without this device because trace drug filling and close shell top position will along the shell wall climb up a small hill under the static electricity function reach suppository sealing part will affect the quality of behind the seal.

3.Stirring barrel speed adjustable system:

Note:because of the drug material different and the viscosity different maybe

the same stirring result can not mix drug uniform before filling so that affect

finished suppository products drug content.

4.Cooling speed adjustable system:

Note:

because of different drug different components maybe need different

cooling speed; when the cooling speed too slow will reduce the whole

machine production efficiency;if the cooling speed too high maybe due to

drug suddenly drop temperature then fracture therefore cooling speed

need adjustable. Screw pump, the liquid medicine runs smoothly, to improve filling accuracy.

5.Shearing granules quantity can adjustable system:

Note:according to customer s requirement can convenient set up finished

products granules as 1/2/3/4/5/6/7 granules. Suitalbe for PVC/PE material.

ketchup production line

ketchup production line

Acceptance inspection--Russian Client

Acceptance inspection--Russian Client

2011 FCE

2011 FCE