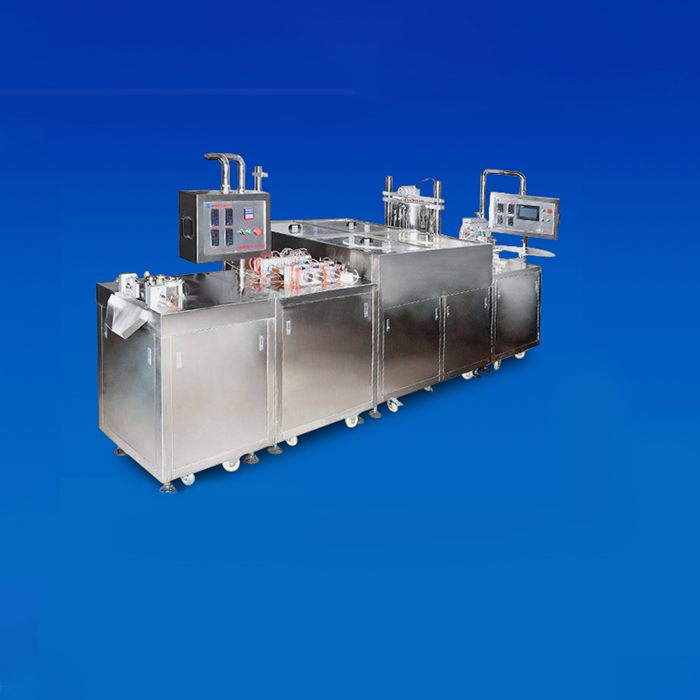

KY-B Semi Automatic Suppository Filling and Sealing Machine

Through PLC on-line detection function, it can do the self-checking alarm especially for the operation fault.

Samples of Suppository

Advantage of Our Machine

1. PLC detection function:

Through PLC on-line detection function, it can do the self-checking alarm especially for the operation fault.

And it can also display the fault reason synchronously, it is easy for the operator to do timely fault removing.

2. The suppository cutting quantity adjustable system.

Remarks: The quantity can be setup as 4/5/6/7 pieces per time for the final product.

3. Stable operation and low failure rate.

Technical Parameters

| production output | 5000-10000 pcs per hour |

| (it can be adjustable according to customer's need) | |

| single dosage | 0.5—5ml |

| dosage allowed | <±2% |

| suppository form | bullet shape, torpedo shape, duck mouth shape |

| or other shapes | |

| suitable base materials | synthesis of glycerin fatty acids、 |

| glycerin gelatin、polyethylene glycol etc.聚成 | |

| liquid barrel | 50L |

| filling volume | |

| working air pressure | 0.6Mpa |

| air consumption | 1.5m3 |

| per min | |

| water consumption | 50kg (cycle using) |

| per hour | |

| working voltage | 380V, 50hz, 3 phases |

| total power | 5KW |

| external dimension | 5155mm×1640mm×1879mm |

| packaging Film | PVC/PE laminated film |

| total weight | 700kg |

ketchup production line

ketchup production line

Acceptance inspection--Russian Client

Acceptance inspection--Russian Client

2011 FCE

2011 FCE