KY-U Full Automatic Suppository Filling and Sealing Machine

Film material on the film s plate(PVC/PE)through the gripping agencies into forming area to preheating film——>forming mold——>blowing film——>blown film forming

triangle knife cut edge technology,the dotted line cut.

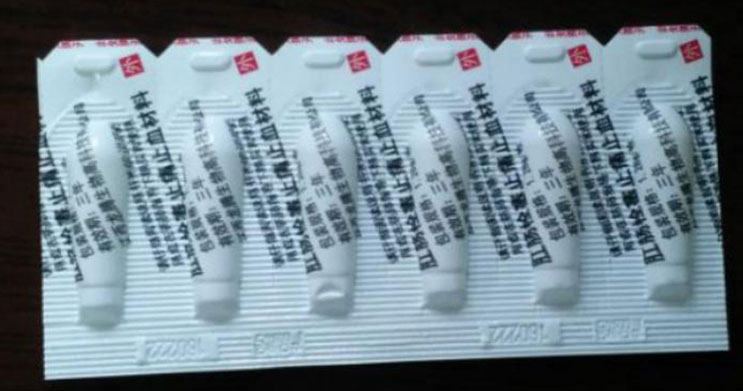

● Suppository Products Samples

● Technical Parameters

| Output | 8000—11000 granules/hour (center distance 17.4) |

| Single dosage | 0.5—5ml |

| Dosage allowed | <±2% |

| Suppository application form | Bullet-head form、torpedo form、duck-mouth form |

| and other special forms | |

| Applicable to the host | Synthesis of glycerin fatty acids、glycerin gelatin、polyethylene glycol etc. |

| Capacity of the liquid barrel | 100L |

| Working atmospheric pressure | 0.6Mpa |

| Consumption gas/minute | 1.5m3 |

| Used water quantity | 50kg /hr(cycle using) |

| The voltage of the power | The three phase AC 380V |

| Total power | 7.5KW |

| External dimension | 3100mm×3480mm×2000mm |

| Total weight | 2000kg |

● Whole Machine Operating Principle

1. Forming part:

Film material on the film s plate(PVC/PE)through the gripping agencies into forming area to preheating film——>forming mold——>blowing film——>blown film forming

triangle knife cut edge technology,the dotted line cut.

2. Filling part:

Seven nozzles filling,for forming suppository one time embedded filling,filling precision ± 2%,material barrel with electric-heating insulation system,top with a stirring motor so that drug keep uniform state,the drug in the barrel through cycle pump into filling nozzles,one time filling the remaining drug cycle through the other end of a raw material barrel to do the next filling.

3. Cooling part:

Filling the entire row of drug finished then into cooling frame,cooling box internal with chiller block,cooling wind through two condensers in the cooling box to cooling suppository on the cooling rack.

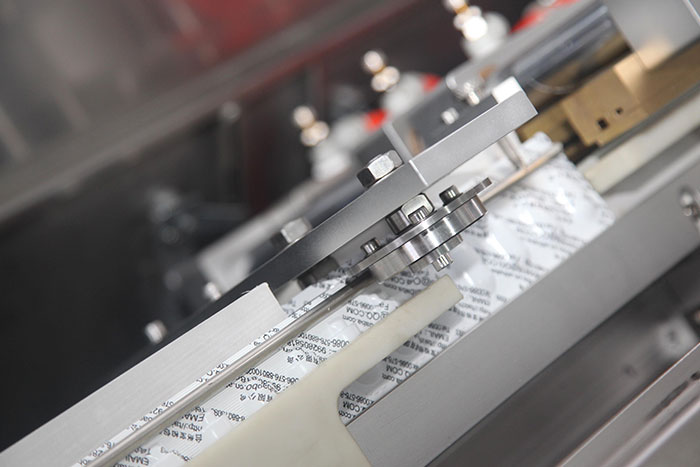

4. Seal tail and type code:

After cooling the solid suppository into sealing area:

pre-heat mold——>seal mold——>type mold.

Then cut the finished products a group for six granules or five granules

(according to customers requirement).

● Equipment advantage

1. PLC inspection function:

through PLC online monitoring function can inspect

automatic running fault and alarm as the same time show the reason of running

fault its convenient operator to remove the fault timely

2. The filling part with removing static electricity system:

Note:before forming shell reach filling place if without this device because trace drug

filling and close shell top position will along the shell wall climb up a small hill under

the static electricity function reach suppository sealing part will affect the quality of

behind the seal

3. Stirring barrel speed adjustable system:

Note:because of the drug material different and the viscosity different maybe

the same stirring result can not mix drug uniform before filling so that affect

finished suppository products drug content.

4. Cooling speed adjustable system:

Note:because of different drug different components maybe need different

cooling speed; when the cooling speed too slow will reduce the whole

machine production efficiency;if the cooling speed too high maybe due to

drug suddenly drop temperature then fracture therefore cooling speed

need adjustable

5. Shearing granules quantity can adjustable system:

Note:according to customer s requirement can convenient set up finished

products granules as 4/5/6/7granules.

suitable for PVC/PE material.

6. Carving print system

It can be printed according to customer's need.

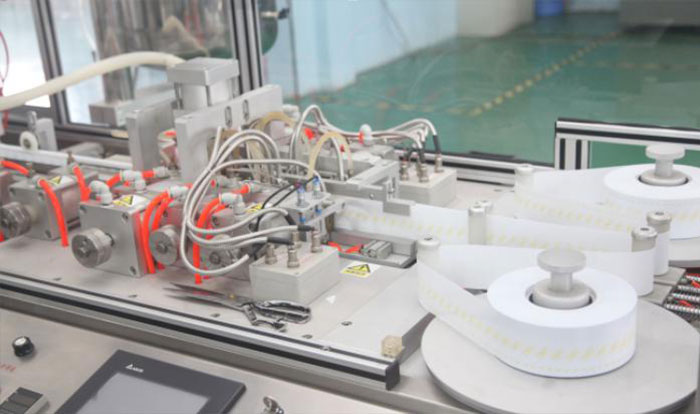

● Photos of Machine in our Factory

ketchup production line

ketchup production line

Acceptance inspection--Russian Client

Acceptance inspection--Russian Client

2011 FCE

2011 FCE